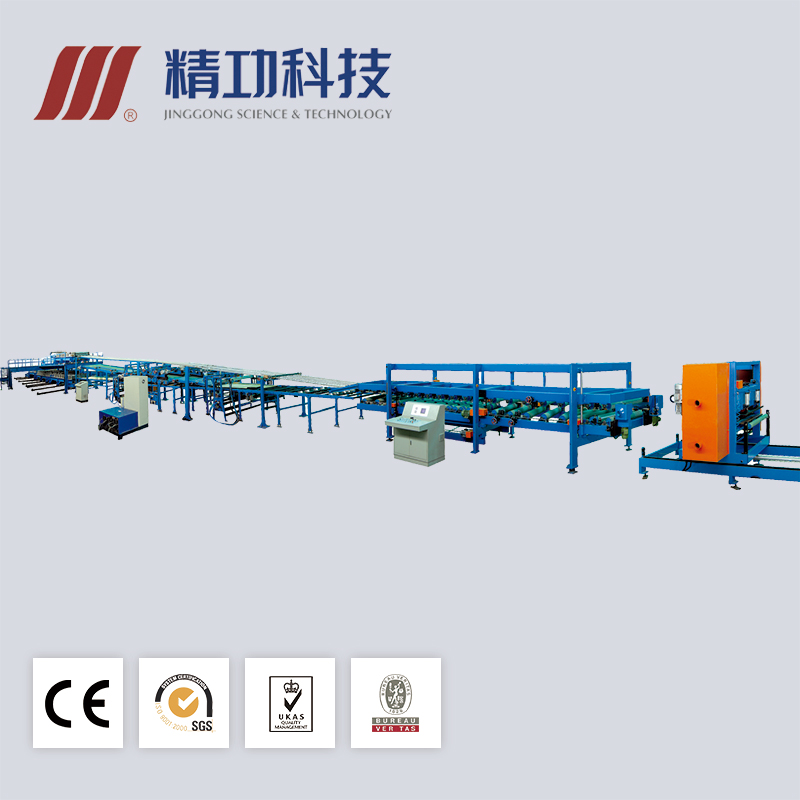

OEM ODM EPS sandwich panel machine

Description

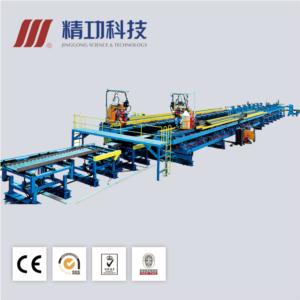

The EPS sandwich panel machine is an advanced laminating solution specifically designed for the production of corrugated sandwich panels. This innovative equipment combines a roll forming machine with a sophisticated sandwich panel laminating system, effectively eliminating the manual lamination process that traditional methods require. The machine operates efficiently, allowing for the independent functioning of both the roll forming machine and the laminating system.

The roll forming machine is equipped with a feeding system, roll forming system, and cutting system, ensuring a seamless production process. Meanwhile, the laminating system features a comprehensive array of components including a decoiler, feeding mechanism, squeezing apparatus, heating unit, and advanced PLC-controlled automatic cutting system. This integration of mechanical and electrical systems results in a highly productive line capable of generating approximately 500,000 square meters of corrugated sandwich panels annually, operating for eight hours a day.

Specifications

| Feature | Description |

|---|---|

| Production Capacity | 500,000 square meters annually (8 hours/day) |

| Components | Feeding system, Roll forming system, Cutting system, Decoiler, Heating unit, Automatic cutting system |

| Production Type | Corrugated sandwich panels |

| Operation Mode | Independent operation of roll forming and laminating systems |

Additional Information

- Eliminates the need for manual lamination

- Integrates advanced mechanical and electrical technology