Description

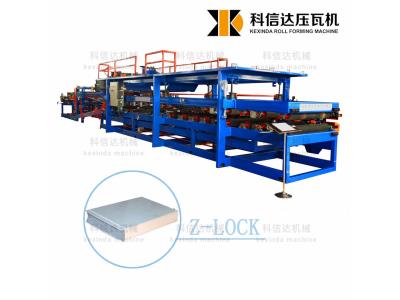

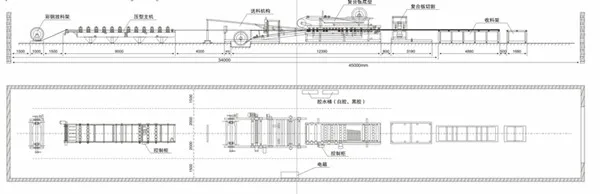

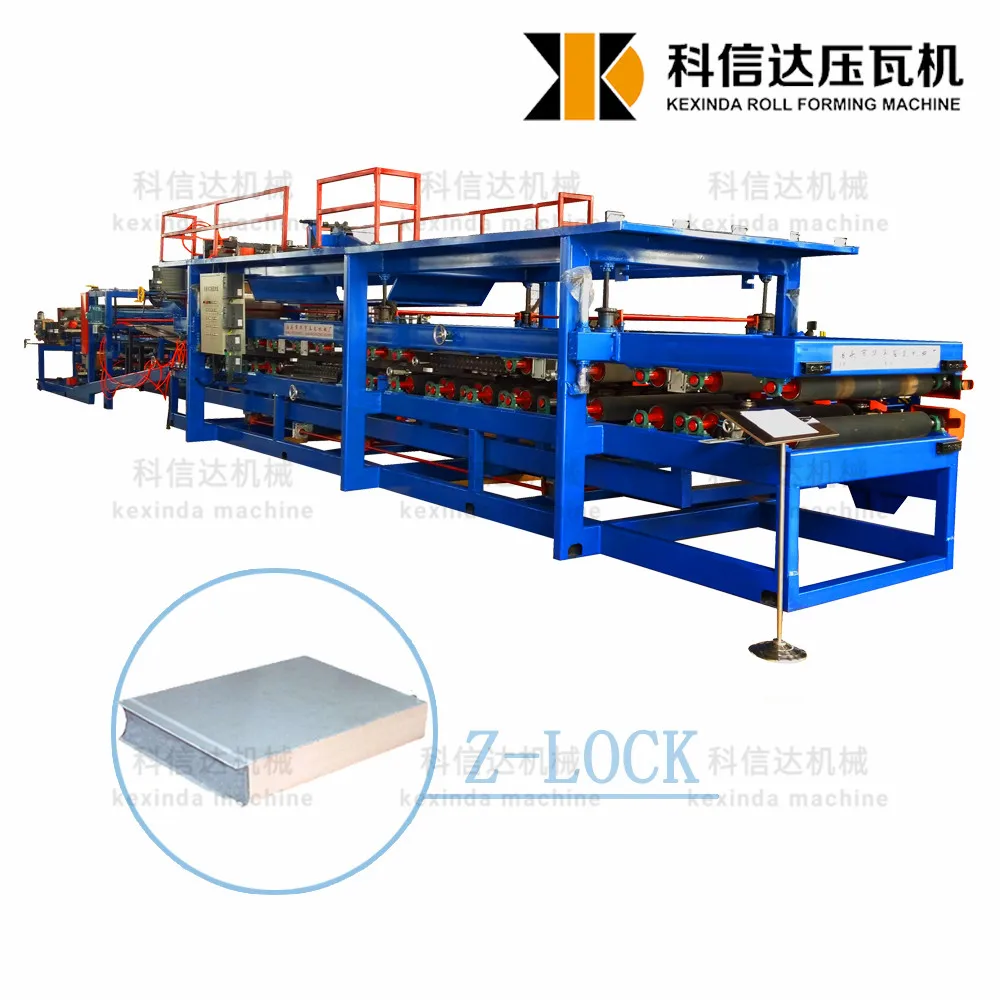

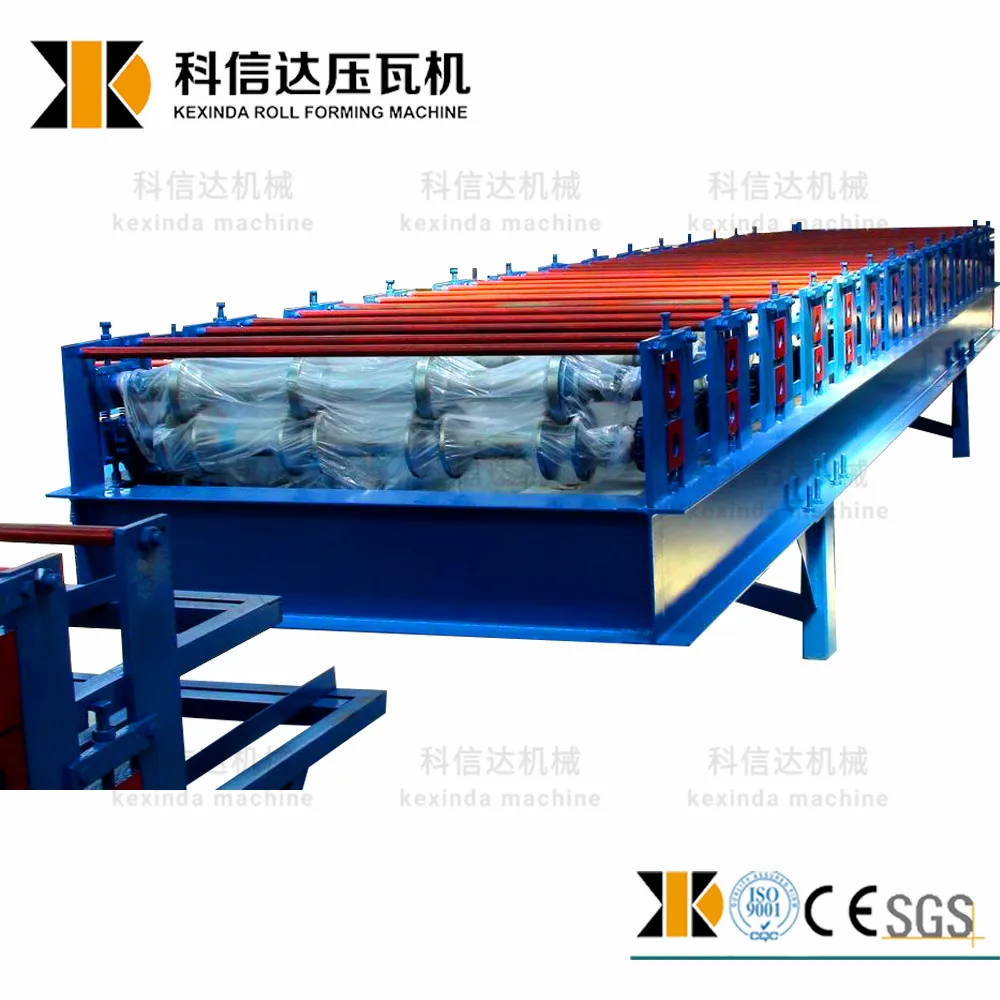

The EPS Sandwich Panel Machine is a cutting-edge production line designed for the efficient manufacturing of sandwich panels. This machine utilizes EPS (Expanded Polystyrene) as its core material, making it ideal for creating lightweight yet durable panels suitable for construction and insulation applications. With a production capacity ranging from 2 to 4.5 meters per minute, it is tailored to meet varying production needs. The system features advanced PLC control for precision and ease of operation, ensuring high-quality output with every run.

Specifications

| Attribute | Details |

|---|---|

| Coil Material | EPS |

| Thickness of the Plate | 0.3-0.8mm |

| Core Thickness | 40-250mm |

| Production Capacity | 4-4.5m/min (fastest), 2-2.5m/min (slowest) |

| Total Power | About 30KW |

| Weight | 25 tons |

| Dimensions of Whole Production Line | About Length 42000mm × Width 3600mm × Height 3300mm |

| Control System | PLC |

Additional Information

For optimal performance, ensure regular maintenance of the machine components and adherence to safety protocols during operation. This machine is designed for high efficiency, making it a valuable asset for any manufacturing facility focused on sandwich panel production.