OEM ODM EPS Sandwich Panel Production Line Chinese Manufacturer

Description

The EPS Sandwich Panel Production Line is a state-of-the-art manufacturing system designed for producing high-quality sandwich panels used in construction and insulation applications. This advanced equipment, suitable for processing EPS, rock wool, and glass silk floss, ensures efficiency and precision in production. The system features a PLC control system that simplifies operation while maintaining high operational stability and precision.

Key features include:

- Coil material compatibility: EPS, rock wool, glass silk floss

- Plate thickness range: 0.3-0.8mm

- Core thickness options: 20-300mm

- Production capacity: Up to 4.5m/min

- Total power requirement: Approximately 30KW

- Weight: 25 tons

- Dimensions: Approximately Length 35000mm × Width 2500mm × Height 2600mm

This production line is ideal for manufacturers looking to enhance their operational capabilities while producing top-quality sandwich panels.

Specifications

| Attribute | Details |

|---|---|

| Coil Material | EPS, rock wool, glass silk floss |

| Plate Thickness | 0.3-0.8mm |

| Core Thickness | 20-300mm |

| Production Capacity | 4-4.5m/min (maximum), 2-2.5m/min (minimum) |

| Total Power | About 30KW |

| Weight | 25 tons |

| Dimensions | Length 35000mm × Width 2500mm × Height 2600mm |

Additional Information

Terms of Payment: 30% of the total contract value is required as a down payment, with the remaining 70% due after inspection by the buyer at the seller’s factory before delivery.

Delivery: Approximately 60 days after receipt of advance payment.

Service: Technicians will be sent to the buyer’s location for machine setup. The buyer is responsible for all related costs, including visas, roundtrip tickets, accommodation, and a daily salary of $60.

Warranty: A 12-month limited warranty covering parts, with shipping costs to be borne by the buyer during the warranty period.

Customization: The manufacturer can design machines according to specific drawings, allowing for changes in plate types as per customer needs.

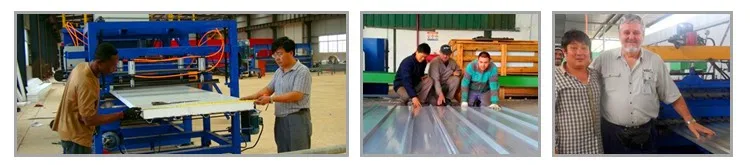

Product Pictures