EPS Sandwich Panel Production Line Chinese Manufacturer

Inquire NowDescription

The EPS Sandwich Panel Production Line is a state-of-the-art manufacturing system designed for producing high-quality sandwich panels with EPS, rock wool, and glass silk floss. This advanced production line features a robust Z-lock design for superior insulation and structural integrity. With its automatic roll forming machine, the line ensures efficient processing and high precision in panel production, making it an ideal choice for construction and insulation applications.

Specifications

| Attribute | Details |

|---|---|

| Coil Material | EPS, rock wool, glass silk floss |

| Plate Thickness | 0.3-0.8 mm |

| Core Thickness | 20-300 mm |

| Production Capacity | 4-4.5 m/min (fastest), 2-2.5 m/min (slowest) |

| Total Power | About 30 KW |

| Weight | 25 tons |

| Control System | PLC control system for easy operation and high precision |

| Dimensions | Length 35000 mm × Width 2500 mm × Height 2600 mm |

Additional Information

Processing Technique: The production line includes a Composite Decoiler, Roll Forming, a laminating system (ribbon, gelatinizing, heating up, compounding, crimping, notching, edge trimmer), cutting system, and Runout Table.

Terms of Payment: 30% down payment via T/T, the remaining 70% after inspection before delivery.

Delivery Time: 60 days after receiving advance payment.

Service: Technicians will assist with installation, with costs for travel and accommodation covered by the buyer.

Warranty: 12 months limited warranty; parts are free during warranty, but shipping costs apply.

Customization: The machine can be designed according to specific drawings and plate types can be adjusted as needed.

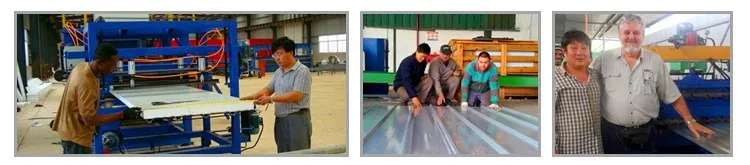

Product Pictures