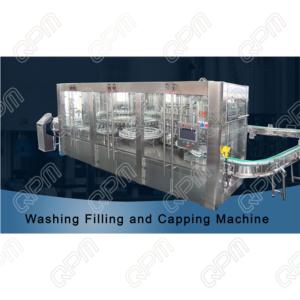

OEM ODM Filling and capping machine

Description

The Filling and Capping Machine is an advanced solution designed for efficient spirit bottling, integrating both filling and capping functionalities in a single unit. This machine optimizes factory space utilization while enhancing operational efficiency through its high degree of automation, significantly reducing labor costs. Meticulously engineered, it prevents secondary pollution during the filling process and guarantees adherence to food hygiene standards. The height of the machine is adjustable, making it versatile for various bottle sizes.

Constructed with high-grade stainless steel in all liquid-contacting components, this machine ensures cleanliness and ease of maintenance. It incorporates Siemens electronics, including PLC, touch screen, and frequency converters for reliable operation. Additionally, it features an overload clutch protection device to safeguard both the bottles and the machine in case of jams. Rigorous fatigue testing of all springs underscores the commitment to quality and stability.

Specifications

| Feature | Description |

|---|---|

| Functionality | Complete filling and capping for spirits |

| Height Adjustment | 160mm to 320mm |

| Filling Precision | 500ml ± 1.5ml |

| Filling Speed | High speed with no spills |

| Materials | High-grade stainless steel |

| Control System | Siemens PLC and touch screen |

| Protection Features | Overload clutch protection device |

| Transmission | Built-in for low noise |

Additional Information

- Automatic positioning for precise capping

- Compatible with bottle heights of 160-320mm

- Optional automatic cap arrangement and loading devices available