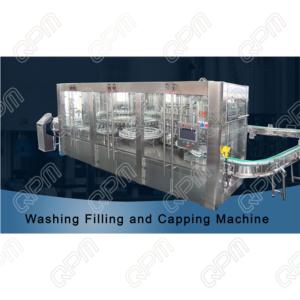

OEM ODM Filling-capping machine

Description

The Filling-Capping Machine is a state-of-the-art monobloc system designed for high-efficiency filling and capping of 0.5-liter bottles, achieving speeds of up to 500 bottles per hour (BPH). This versatile machine is suitable for various industries, including food, pharmaceuticals, beverages, tobacco, cosmetics, toys, and electronics. Its innovative design employs a step-by-step operation principle, allowing for a compact structure with each filling phase centered around a central star, enabling bottles to be handled in groups of three.

One of the standout features of this GF3-1 model is its rapid change-over procedure, significantly reducing downtime compared to traditional linear or rotating machines. The machine’s flexibility is further enhanced with a valve that allows for precise adjustments to the filling cycle via PLC, accommodating a range of liquids by simply changing the filling valve. Built with solid and durable materials, this machine ensures a long operational life while maintaining a compact footprint, making it ideal for installations in tight spaces and for optimizing labor costs.

Specifications

| Feature | Description |

|---|---|

| Filling Speed | Up to 500 BPH for 0.5L bottles |

| Design | Monobloc with step-by-step operation |

| Applications | Food, medicine, beverages, tobacco, cosmetics, toys, electronics |

| Adjustability | Height adjustment for different devices |

| Construction | Solid and durable; motors and transmissions below base |

| Cap Orientation | Dedicated device for cap transfer above capping module |

Additional Information

- Flexible filling cycle adjustments via PLC.

- Compact frame design for space efficiency.

- Single-head capping for consistent application.