OEM ODM Four axis machining center

Description

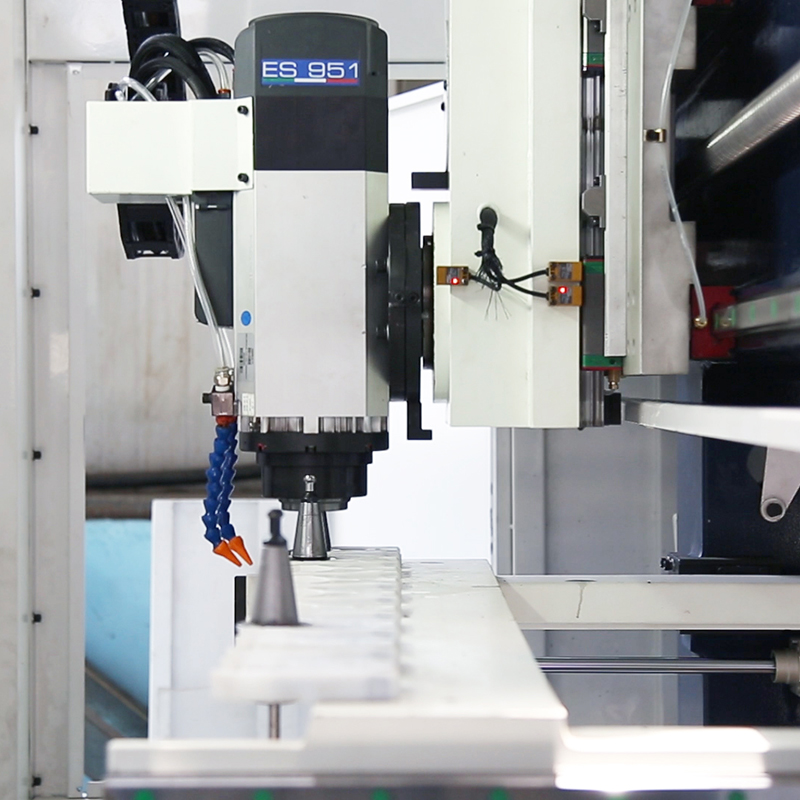

The Four Axis Machining Center is designed for advanced industrial CNC profile machining, providing exceptional versatility and precision for aluminum and light alloy profiles, as well as U-PVC processing. This state-of-the-art machine features a milling head capable of drilling at angles from 90° to -90°, allowing for intricate designs and complex operations.

With its ability to perform multiple operations such as milling, drilling, tapping, and grooving in one seamless process, this machining center ensures efficiency and accuracy. Its advanced technology includes imported high-precision components, ensuring smooth motion and high positioning accuracy. The user-friendly Windows-based operation system enhances ease of use, making it suitable for various applications in manufacturing and fabrication.

Specifications

| Attribute | Details |

|---|---|

| Air Consumption | 60L/min |

| Input Power | 16.5KW |

| X-axis Feed Rate | 0~60m/min |

| Z-axis Feed Rate | 0~30m/min |

| Main Shaft Rotation Range | -90°~ +90° |

| Processing Range (Top Surface) | 7000X900X260mm |

| Tool Magazine | 9 tool positions |

| Diameter of Blade | Ø80~Ø150mm |

| Positioning Accuracy | ±0.03mm |

| Machine Size | 9000x2200x2250mm |

| Air Pressure | 0.5-0.8Mpa |

| Power Specification | 3N~50HZ 380V or customized |

| Weight | 4300kg |

Additional Information

| Main Accessory | Details |

|---|---|

| CNC System | PA (Germany) |

| Servo Motor | YASIKAWA (Japan) |

| Spindle | HSD (Italy) |

| Square Rail | HIWIN (Taiwan) |

| Ball Screw | PMI (Taiwan) |

| Rack | APEX (Taiwan) |

| Electric Button and Switcher | Schneider (France) |

| Air Cylinder | AirTAC (Taiwan) |