Description

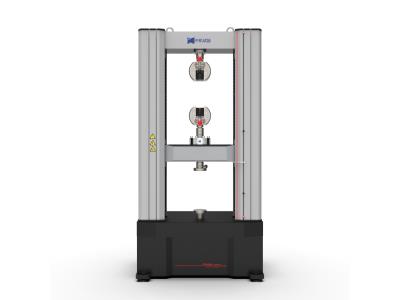

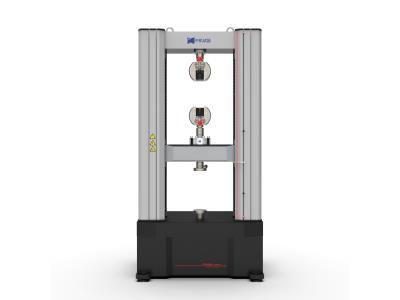

The G series high frequency fatigue testing machine is an advanced electromagnetic excitation resonance type testing equipment, designed to evaluate the anti-fatigue fracture performance of various metal materials and components. With its digital pulse width modulator and intelligent force amplifier, this machine ensures precise testing and reliable results. Its innovative upper vibration starting structure allows for larger space and better sample clamping, while the intelligent air gap structure facilitates easy initiation of vibration.

This machine features a real-time display of experimental waveforms, average load values, alternating load peak values, resonant frequencies, and the number of cycles, providing comprehensive insights into the testing process. The G series also excels in alignment and coaxiality, minimizing lateral forces for accurate testing. Its concise design allows for convenient operation without the need for cooling water or hydraulic oil, ensuring low energy consumption and high efficiency.

Ideal for a variety of applications, this testing machine is widely utilized in the automotive, aerospace, and metallurgy industries, as well as in universities and research institutes. It can perform various fatigue tests, including symmetrical and asymmetrical fatigue tests, unidirectional pulsating fatigue tests, block spectrum fatigue tests, and modulation control fatigue tests, making it an essential tool for quality inspection and new material research and development.

Specifications

| Attribute | Details |

|---|---|

| Type | High Frequency Fatigue Testing Machine |

| Operation Principle | Electromagnetic Excitation Resonance |

| Testing Capabilities | Fatigue Life and Fatigue Limit Testing |

| Applications | Automobile, Aerospace, Research, Quality Inspection |

| Features | Real-time Data Display, Low Energy Consumption |

Additional Information

The G series high frequency fatigue testing machine is equipped with special fixtures tailored for various materials and parts, including gears, bolts, chains, connecting rods, and fine steel bars, ensuring versatility in testing applications. Its user-friendly design and operational efficiency make it a pivotal asset in any research or testing facility.