Description

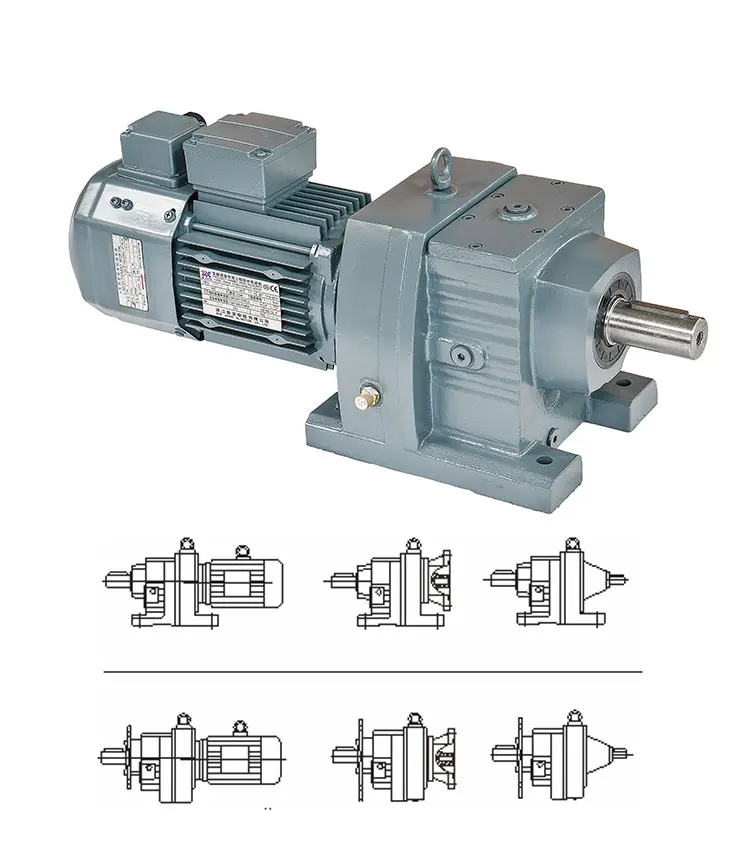

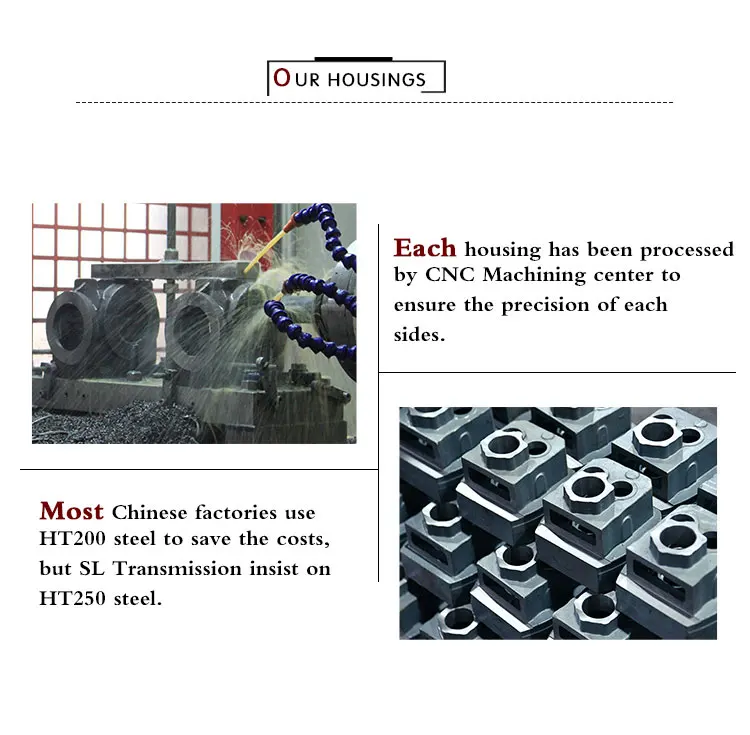

Introducing the Gearbox Motor Reducer HT250, an advanced solution engineered for high performance in various industrial applications. This helical gearmotor, made from durable HT250 high-strength cast iron, operates efficiently at both 220V and 380V across 50HZ and 60HZ. Its compact design not only conserves space but also provides substantial torque transmission while minimizing noise levels and maximizing mechanical efficiency. The gears are crafted from 20CrMnTi alloy steel, heat-treated to achieve a surface hardness of HRC58° to 62°, ensuring longevity and reliability in demanding environments.

The Gearbox Motor Reducer HT250 is ideal for a wide range of industries, including paper making, printing machinery, chemical and pharmaceutical manufacturing, as well as petroleum and mining operations. This versatility makes it a valuable asset in any production line, enhancing operational productivity and efficiency.

Specifications

| Attribute | Details |

|---|---|

| Housing material | HT250 high-strength cast iron |

| Housing hardness | HBS190-240 |

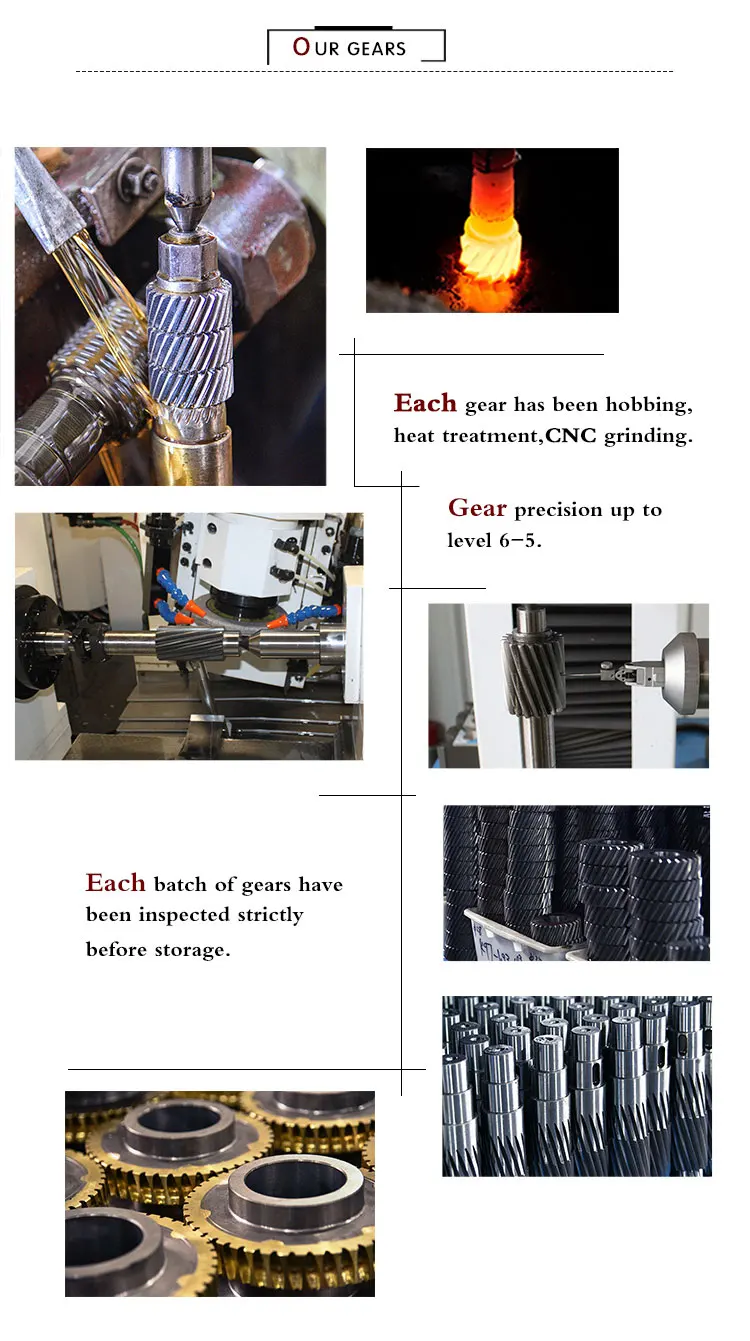

| Gear material | 20CrMnTi alloy steel |

| Surface hardness of gears | HRC58°~62° |

| Gear core hardness | HRC33~40 |

| Input / Output shaft material | 42CrMo alloy steel |

| Input / Output shaft hardness | HRC25~30 |

| Machining precision of gears | Accurate grinding, 6~5 Grade |

| Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

| Heat treatment | Tempering, cementing, quenching, etc. |

| Efficiency | 94%~96% (depends on the transmission stage) |

| Noise (MAX) | 60~68dB |

| Temp. rise (MAX) | 40℃ |

| Temp. rise (Oil)(MAX) | 50℃ |

| Vibration | ≤20μm |

| Backlash | ≤20Arcmin |

| Brand of bearings | China Top brand HRB, LYC, ZWZ, or other brands requested, NSK… |

| Brand of oil seal | NAK—Taiwan or other brands requested |

Additional Information

- Ideal for use in various industries including chemical, pharmaceutical, and printing.

- Designed for high efficiency and low noise operation.

- Maintenance recommendations include regular lubrication with specified oils.