Description

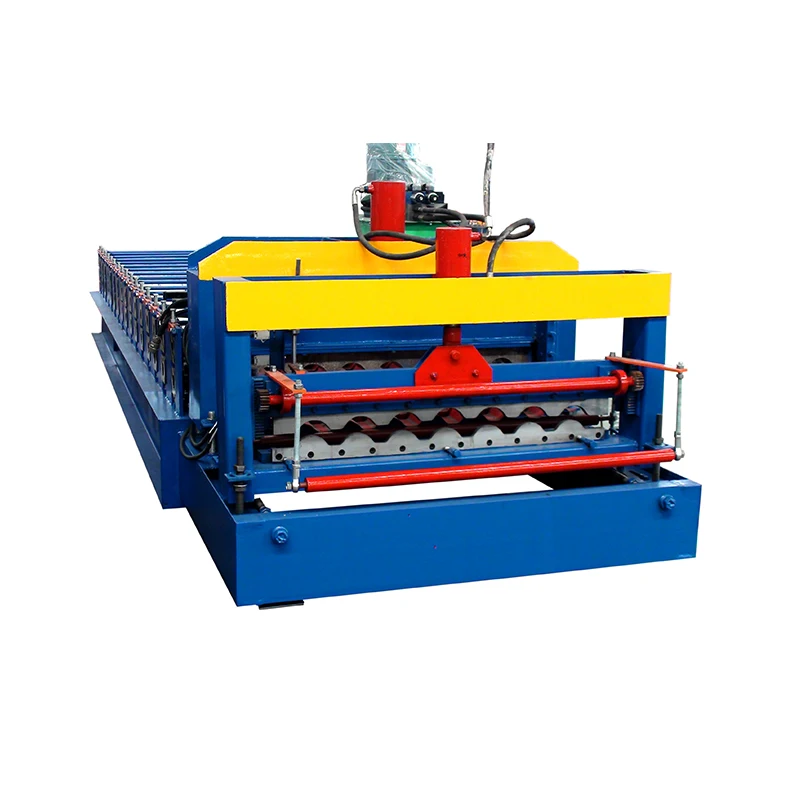

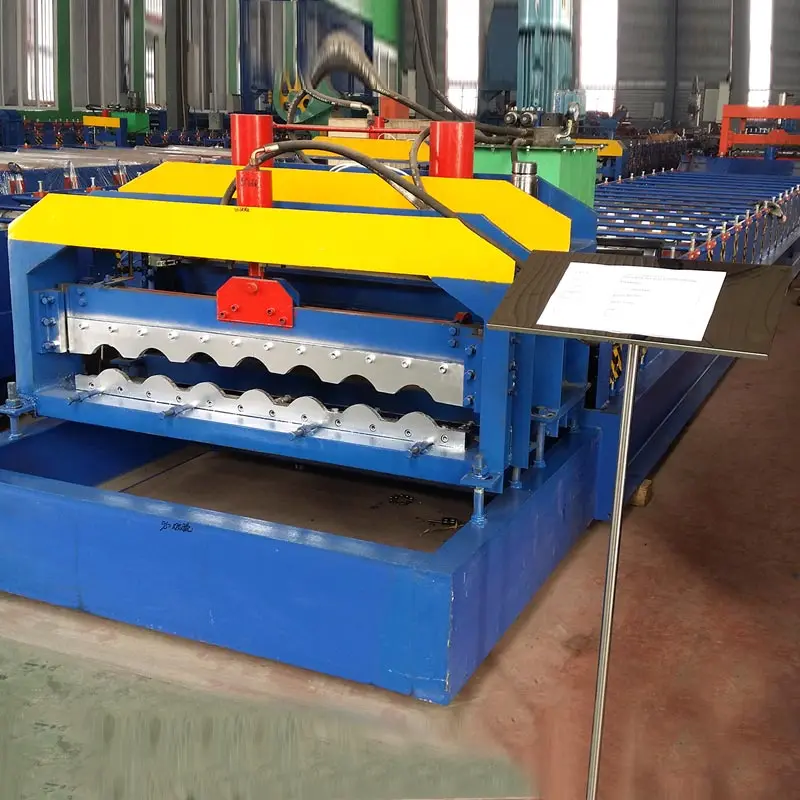

Glazed Tile Roll Forming Equipment is a versatile building material machinery designed for efficiently producing high-quality roof panels. This advanced equipment includes key components such as a man-made uncoiler, a roll forming machine, a computer control system, and a hydraulic control system. Its robust construction ensures durability and reliability, making it suitable for various industrial applications, including civilian buildings, warehouses, and easy steel building manufacturing. The aesthetically pleasing design and outstanding performance make it an ideal choice for modern construction projects.

Specifications

| No. | Main Parameter | Details |

|---|---|---|

| 1 | Suitable to Process | Color Steel Plate |

| 2 | Width of the Plate | 1200 mm |

| 3 | Rollers | 18 Rows |

| 4 | Dimensions | 8.0 x 1.6 x 1.5 m |

| 5 | Power | 4 + 3 kW |

| 6 | Thickness of the Plate | 0.3 – 0.8 mm |

| 7 | Productivity | 8 – 12 m/min |

| 8 | Diameter of the Roller | Φ80 mm |

| 9 | Weight | About 6.8 T |

| 10 | Voltage | 380 V 50 Hz 3 phases |

| 11 | Rolling Material | Carbon Steel 45# |

| 12 | Material of the Cutting Plate | Cr12 |

| 13 | Processing Precision | Within 1.00 mm |

| 14 | Control System | PLC Control |

Additional Information

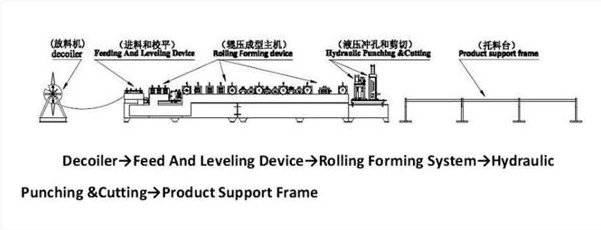

The production flow of the roll forming machine includes:

- Decoiling the sheet

- Sheet guiding

- Roll forming

- Measure length

- Cutting the panel

- Panels to the supporter

Packaging Details: The main machine is shipped nude in the container, while the computer control box is securely packed with wooden packaging.

Delivery Time: 30 workdays after receiving a 30% advance payment.

Images