glazed tile roll forming equipment building material machinery

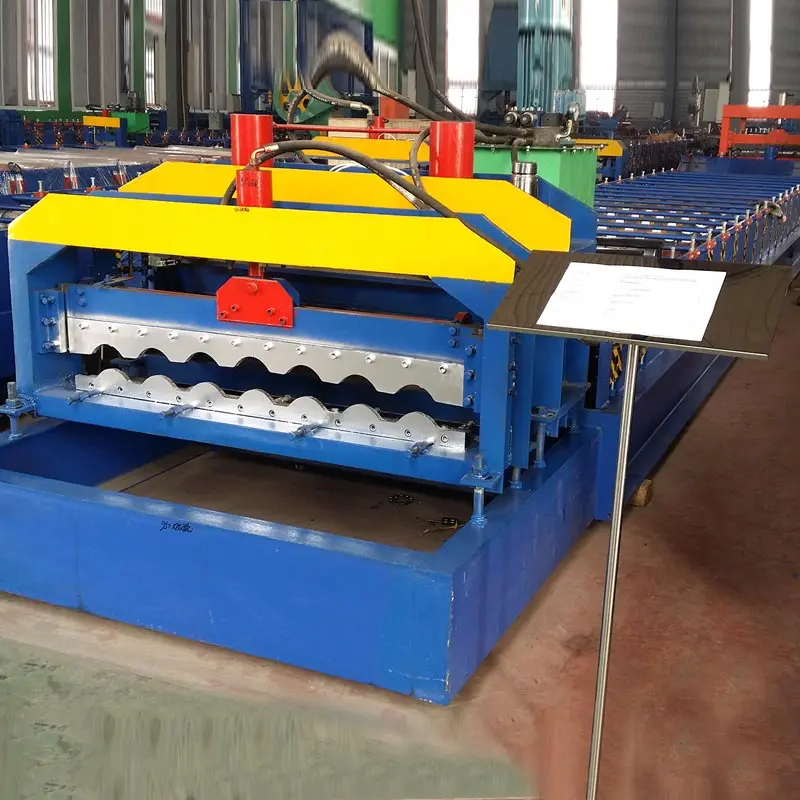

Inquire NowIntroducing our advanced Glazed Tile Roll Forming Equipment, designed for the production of high-quality building materials. This versatile machinery includes essential components such as a man-made uncoiler, a precision roll forming machine, a computer control system, and a hydraulic control system for efficient operation. Ideal for a variety of applications, our equipment is widely used in industrial factories, civilian buildings, warehouses, and the manufacturing of easy steel structures. With its attractive design and robust durability, this roll forming equipment meets the diverse needs of the construction industry.

| No. | Main Parameter | Details |

|---|---|---|

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | 1200mm |

| 3 | Rollers | 18 rows |

| 4 | Dimensions | 8.0*1.6*1.5m |

| 5 | Power | 4+3kw |

| 6 | Thickness of the plate | 0.3-0.8mm |

| 7 | Productivity | 8-12m/min |

| 8 | Diameter of the roller | Φ80mm |

| 9 | Weight | About 6.8T |

| 10 | Voltage | 380V 50Hz 3phases |

| 11 | Rolling material | Carbon Steel 45# |

| 12 | Material of the cutting plate | Cr12 |

| 13 | Processing precision | Within 1.00mm |

| 14 | Control system | PLC control |

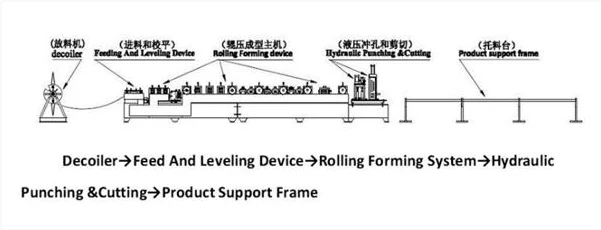

All technical parameters can be customized according to user needs. The production process includes decoiling the sheet, guiding the sheet, roll forming, measuring the length, cutting the panel, and transferring panels to the supporter.

Packaging details: The main machine is shipped nude in the container, while the computer control box is securely packed with wooden materials. Delivery is scheduled for 30 workdays after the receipt of a 30% advance payment.