Description

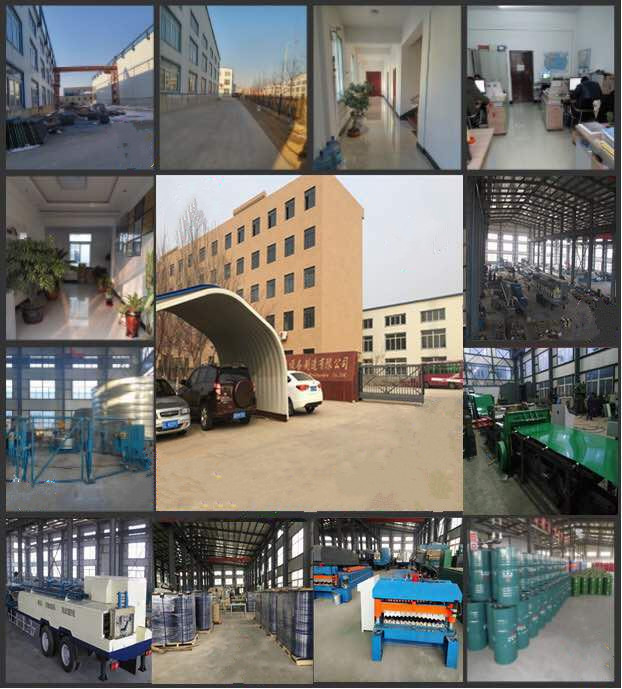

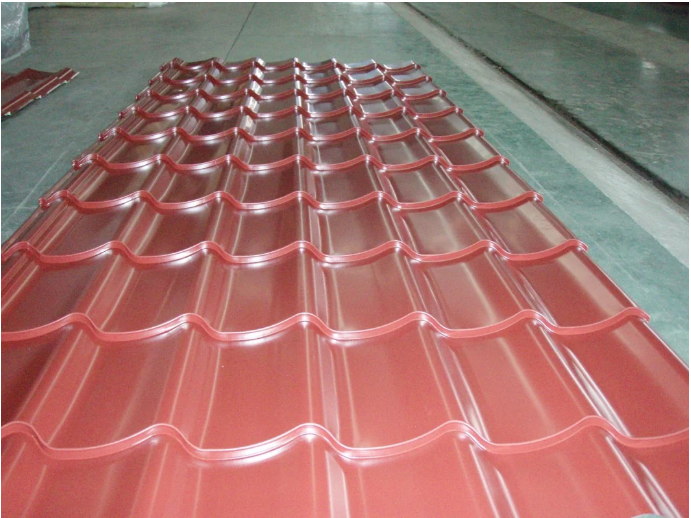

The Glazed Tile Steel Profile Roll Forming Machine is an advanced industrial solution designed for the production of high-quality glazed tile profiles. Engineered for efficiency, this machine features a robust construction that ensures durability and long operational life. With an impressive working speed of 12-15 meters per minute, it allows for high-volume production while maintaining precise specifications for every tile. Our dedicated professional engineering team is ready to customize designs based on specific customer needs, ensuring tailored solutions that meet diverse market demands. In addition, we offer overseas technical guidance and support, enhancing the user experience and operational efficiency.

The machine is built using superior materials, including a welded 350H beam steel frame, ensuring structural integrity and stability during operation. With its user-friendly design, the machine simplifies the production process, providing a seamless workflow from loading to cutting. After-sales service is a priority, with timely follow-ups and engineering advice available as needed. This machine is a testament to our commitment to quality, reasonable pricing, and excellent customer service.

Specifications

| Attribute | Details |

|---|---|

| Production Name | BH Glazed Tile Roll Forming Machine |

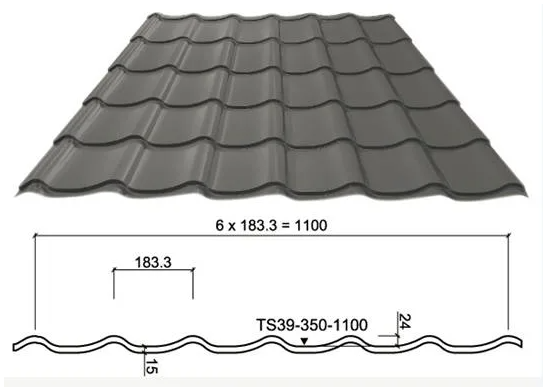

| Specification of Rolling Material | 1250×(0.4-0.8)×L, Yield Strength ≤250MPa |

| Working Speed | 12-15m/min |

| Roller Steps | 16 Steps |

| Frame of Machine | Welded with 350H Beam Steel |

| Thickness of Wallboard | 16mm |

| Roller Material | Superior 45# Forged Steel with Hard Chromium Plated |

| Shaft Material | Superior 45# Forged Steel Quenching and Tempering |

| Main Shaft Diameter | ¢70 mm |

| Main Motor Power | 5.5KW |

| Hydraulic Station Power | 4.0KW |

| Hydraulic Station Pressure | 8 -12MPa |

| Electric Control System | Adopts PLC |

| Machine Size | 7500x1700x1400mm |

Additional Information

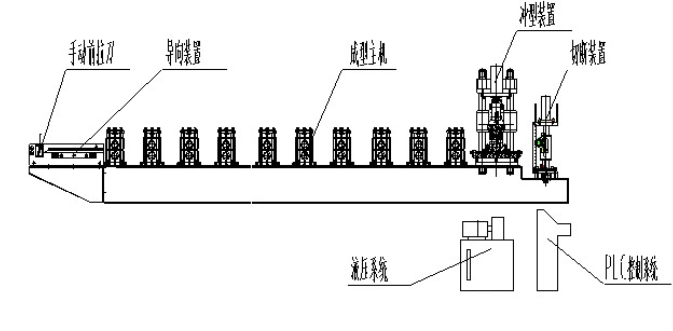

- Working flow: Loading → De-coiling & Feeding → Adjusting & Guiding → Roll Forming → Punching after Roll Forming → Cutting → Run Out Table