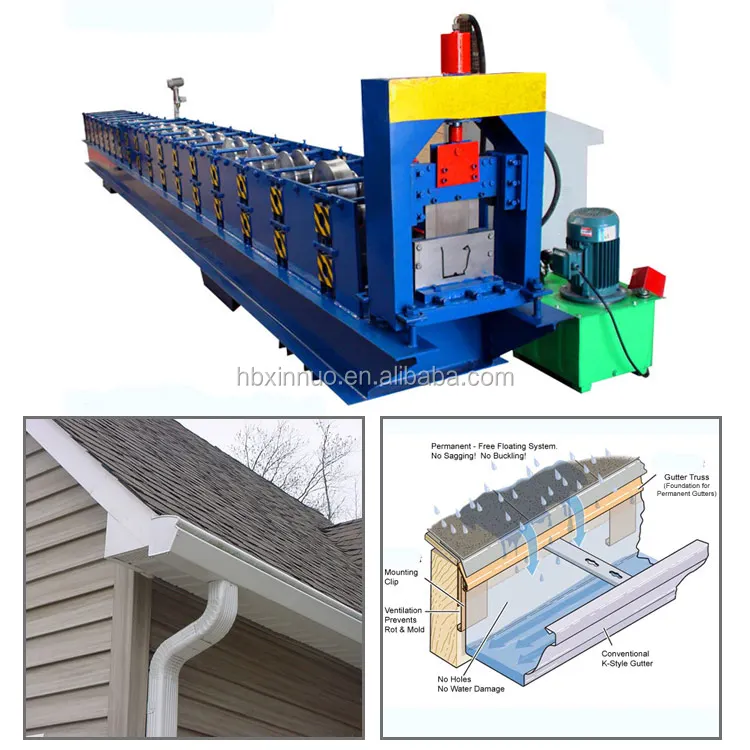

gutter cold rolling machine

Inquire NowThe gutter cold rolling machine is a versatile solution designed for producing drywall profiles and metal roofing components. This high-performance machine is ideal for manufacturers looking to enhance their production capabilities and efficiency. Its advanced technology ensures precise shaping and cutting of various steel plates, making it an essential tool for any metalworking shop.

Product Features:

– Suitable for color steel plates with thickness ranging from 0.3mm to 1.0mm.

– Customizable feeding and effective widths based on user requirements.

– High production speed of 8-12 meters per minute.

– Equipped with a robust Delta PLC control system for reliable operation.

Specifications

| Attribute | Details |

|---|---|

| Suitable Steel Plate | Color steel plate |

| Thickness | 0.3-1.0mm |

| Feeding Width | As user needs |

| Effective Width | As user needs |

| Production Speed | 8-12m/min |

| Roller Stand | 12 rows |

| Roller Diameter | 52mm |

| Main Power | 4kw |

| Pump Power | 3kw |

| Side Panel Thickness | 14mm |

| Roller Material | Carbon 45# steel |

| Blade Material | Cr12, quenched, Cr-plating size 0.05mm |

| Control System | Delta PLC control |

| Main Structure | 300mm H-Beam |

Additional Information

Components Included:

| No. | Item | Unit | Qty |

|---|---|---|---|

| 1 | Manual Decoiler | set | 1 |

| 2 | Main Roll Forming Machine | set | 1 |

| 3 | Main Machine of Composting | set | 1 |

| 4 | PLC Control Box | set | 1 |

| 5 | Supporter Table | set | 1 |

Workflow: Decoiler → Roll Forming → PLC System → Hydraulic System → Cutting → Output Table

Packaging Details: The main machine is nude, while the computer control box is packed with a wooden frame. Delivery time is approximately 20 days.

Product Pictures