Description

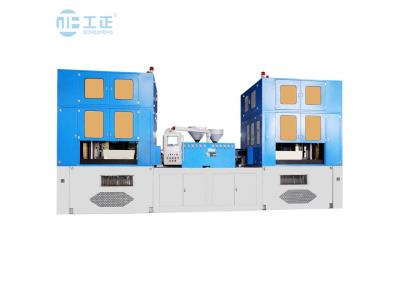

GZ700-FSIII is a state-of-the-art one-step, four-station injection stretch blow molding machine specifically designed for producing large capacity plastic containers suitable for both household and commercial applications. This innovative machine features an integrated system that combines injection, temperature control, stretch and blow molding, and ejection processes into a compact structure. By utilizing the residual temperature to blow the bottle directly, it eliminates the need to reheat the preform, resulting in significant energy savings while enhancing the bottle’s toughness, anti-breaking index, and transparency.

Specifications

| Specification Item | Unit | 700-H | 750-H |

|---|---|---|---|

| Screw Diameter | mm | 75mm/1:20 | 75mm/1:20 |

| Maximum Turning Radius | mm | 700 | 750 |

| Injection Capacity | Cm³ | 1103 | 1103 |

| Injection Locking Force | T | 22 | 22 |

| Blow Molding Locking Force | T | 60 | 60 |

| Opening Stroke of Bottle Mold | mm | 150 (one side) | 150 (one side) |

| Working Pressure | kgf/cm² | 8 | 8 |

| Blow Bottle Pressure | kgf/cm² | 35 (PC Material) | 35 (PC Material) |

| Motor Power | kW | 37 + 22 = 59 kW | 45 + 30 = 75 kW |

| Hydraulic System Pressure | Mpa | 14 | 14 |

| Heating Capacity | kW | 25 | 25 |

| Machine Weight | T | ≈15 | |

| Dimension (L*W*H) | m |

| Volume | Mold Cavity |

|---|---|

| 10L~20L | 1 cavity |

Additional Information

For optimal performance, ensure regular maintenance of the machine, and follow the manufacturer’s guidelines for operation. This machine is ideal for high-volume production and is designed to deliver exceptional efficiency and product quality.