Description

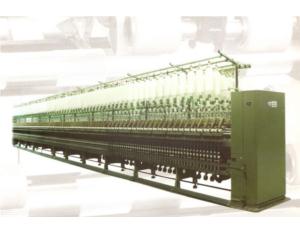

High production and high-speed spun-laced non-woven equipment is designed to meet the growing demands of the non-woven fabric industry. This complete set of equipment integrates advanced technology for the efficient production of non-woven fabrics, which are versatile materials widely used across various sectors including hygiene products and industrial applications.

The equipment features an innovative production line that encompasses all essential processes: opening, carding, drying, and lapping. With the capacity to produce materials ranging from 35g/m2 to 220g/m2, it caters to diverse manufacturing requirements. Each component is crafted with precision from high-quality materials, ensuring durability and longevity.

Equipped with state-of-the-art fittings such as PLC systems, inverters, water needle plates, and high-pressure pumps sourced from renowned manufacturers, this equipment guarantees optimal performance. Additionally, it offers comprehensive services including engineering design, equipment fitting, and installation debugging, making it a valuable asset for any facility looking to enhance its production capabilities.

Specifications

| Attribute | Details |

|---|---|

| Production Capacity | 35g/m2 to 220g/m2 |

| Processes Included | Opening, Carding, Drying, Lapping |

| Equipment Features | PLC, Inverter, Water Needle Plate, High-Pressure Pump |

| Material Quality | High-Precision Components |

Additional Information

This equipment not only streamlines the production process but also enhances efficiency through its robust design and high-quality fittings. It is ideal for manufacturers looking to expand their product line in the non-woven fabric market.