Description

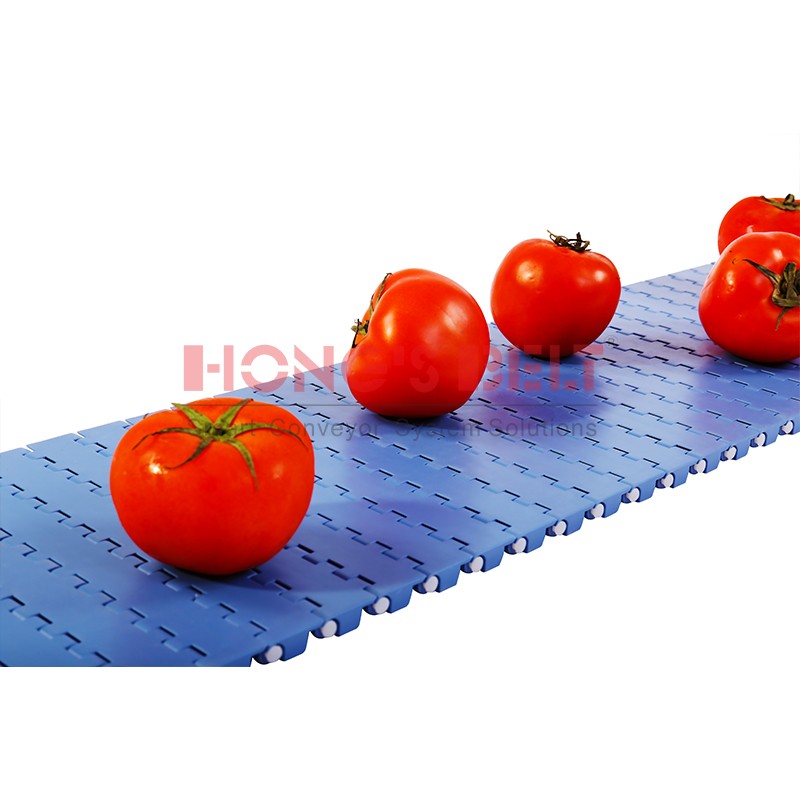

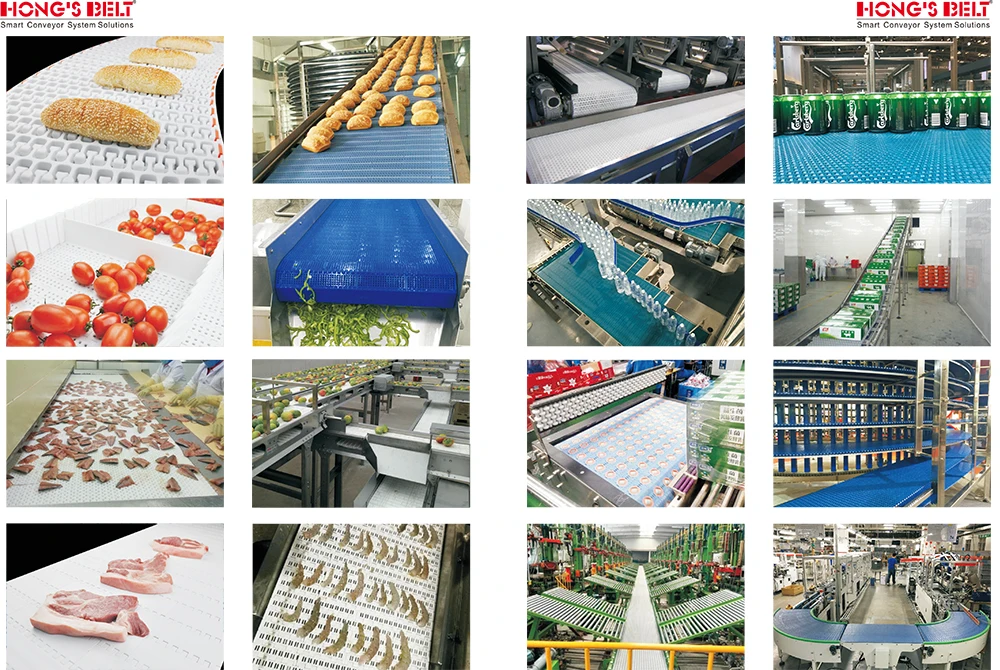

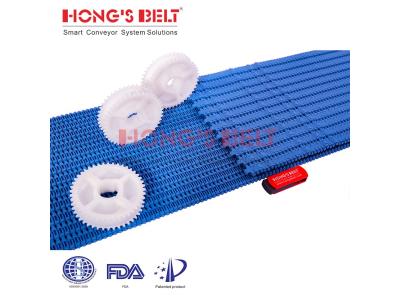

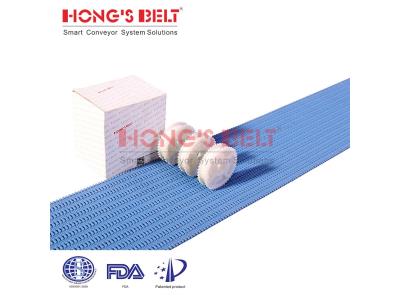

The HONGSBELT HS-2500A modular plastic conveyor belt is specifically designed for food processing applications, providing exceptional performance and durability. This innovative conveyor belt is made from high-quality materials, including PP, POM, PE, and PA, ensuring it meets the rigorous demands of the food industry. Its modular design allows for easy installation and maintenance, making it ideal for various food processing tasks such as meat, poultry, seafood, bakery, and snack food handling. With a range of color options and robust construction, the HS-2500A stands out as a reliable choice for manufacturers looking to enhance their production efficiency.

Specifications

| Attribute | Details |

|---|---|

| Type | HS-2500A |

| Pitch | 25.4mm |

| Thickness | 10mm |

| Minimum Width | 50mm |

| Open Area | 0% |

| Approved | FDA, EU |

| Rod Diameter | 4.9mm |

| Flight | Yes |

| Side Guard | No |

| Curve | No |

| Material | PP, POM, PE, PA |

| Color | White, Blue, Gray, Nature, Dark-brown |

| Working Temperature | -40°C to 260°C |

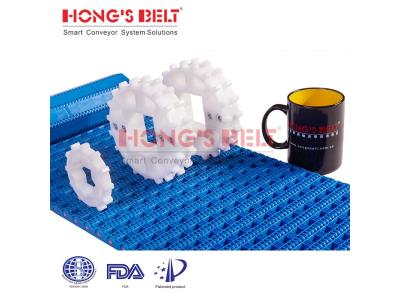

| Sprocket Dimensions |

Sprocket Size: 8T-2R, 10T-2R, 12T-2R, 15T-2R, 18T-2R, 20T-2R, 20T-2R-Split Bore Size: square bore and round bore |

| Application |

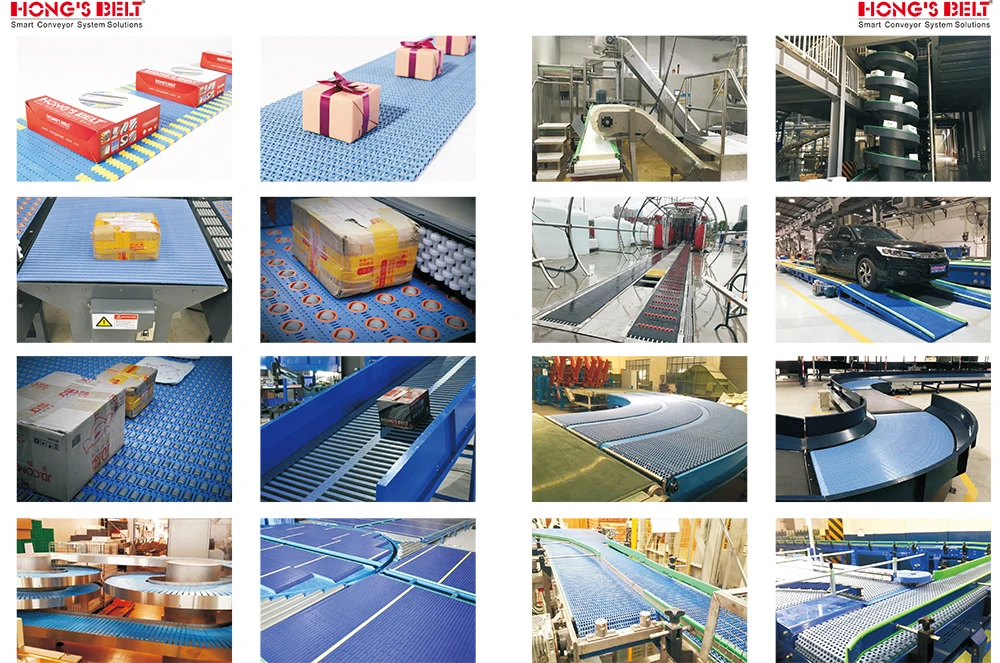

Food Industry: Meat (beef & pork), Poultry, Seafood, Bakery, Snack Food (pretzels, potato chips, tortilla chips), Fruits & Vegetables Non-food Industry: Automotive, Tire manufacturing, Packaging, Printing/Paper, Postal, Corrugated cardboard, Can manufacturing, PET manufacturing, and Textile |

| Advantages | Floating in water, food defrosting, over 10 times longer life compared to traditional conveyor belts, maintenance-free, reduces pollution, food-approved materials, easy to clean, and high load capacity (up to 1.2 tons/square meter). |

Additional Information

For optimal performance and longevity, it is important to regularly clean the conveyor belt and ensure it is operated within the specified temperature range. The HS-2500A is designed to be maintenance-free, enhancing efficiency and reducing downtime in food processing operations.