Description

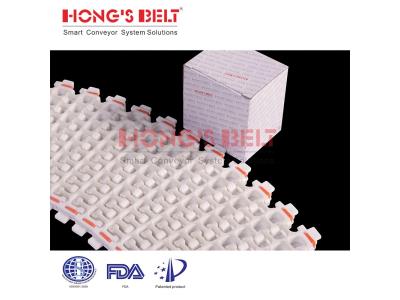

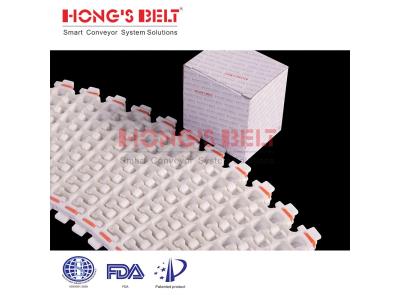

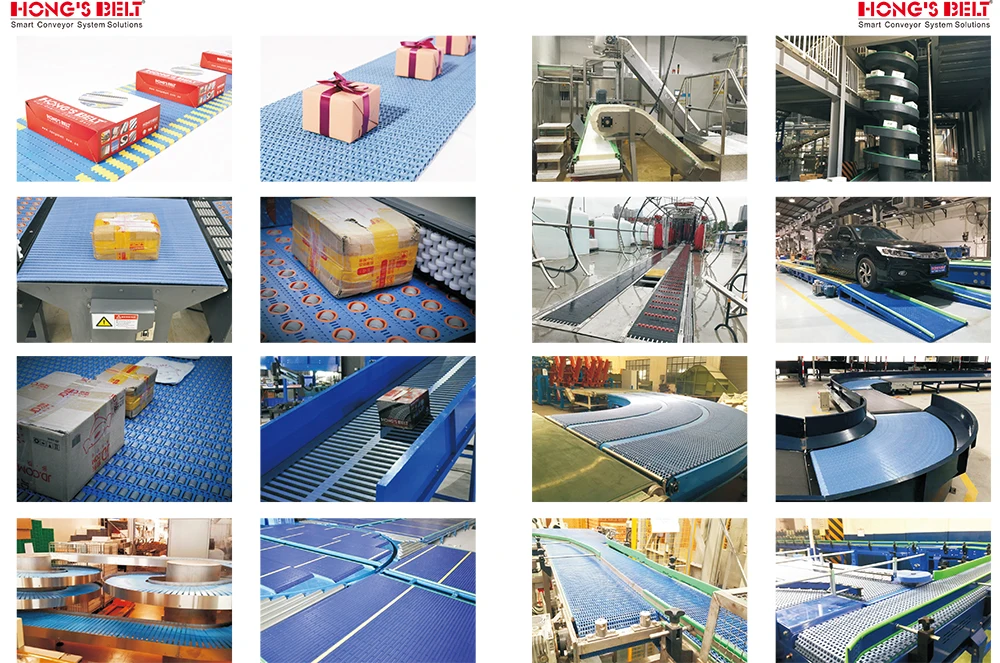

The HONGSBELT HS-300B-PLUS-EL is a state-of-the-art curved modular plastic conveyor belt designed specifically for inclined conveyors. This versatile conveyor solution features a robust construction ideal for various industries, particularly in food handling and manufacturing sectors. With its modular design, the HS-300B-PLUS-EL offers flexibility for different applications and ensures seamless operations in transporting goods.

Key Features:

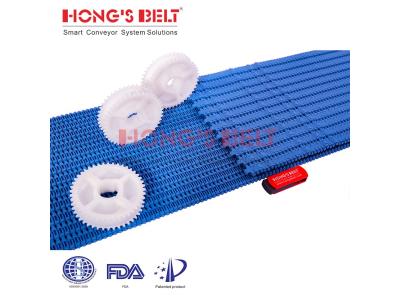

- Modular plastic structure with optional side walls and cleats

- Durable materials suitable for extreme temperatures ranging from -40°C to 260°C

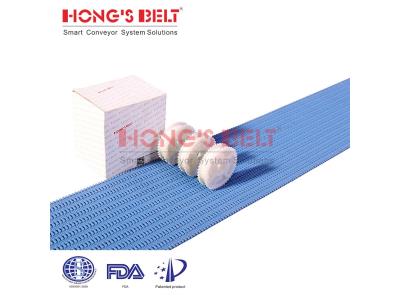

- High open area of 52% allowing for optimal fluid flow

- FDA and EU approved materials ensuring safety in food applications

- Maintenance-free operation with a long lifespan, exceeding traditional conveyor belts

- Ability to float in water, making it ideal for defrosting food

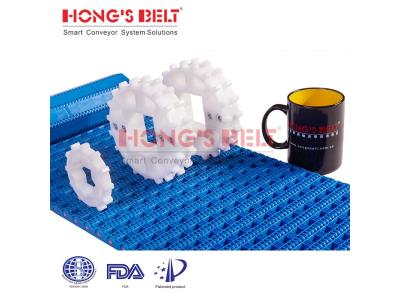

- High load capacity of up to 1.2 tons per square meter

Specifications

| Attribute | Details |

|---|---|

| Type | HS-300B-PLUS-EL |

| Pitch | 45mm |

| Thickness | 18mm |

| Minimum Width | 242mm |

| Open Area | 52% |

| Approved | FDA, EU |

| Rod Diameter | 5.8mm |

| Flight | No |

| Side Guard | No |

| Curve | Yes |

| Material | PP, POM, PE, PA |

| Color | White, Blue, Gray, Nature, Dark-brown |

| Working Temperature | -40°C to 260°C |

| Sprocket Dimensions |

Sprocket Size: 8T, 12T Bore Size: square bore and round bore |

| Application |

Food Industry: Meat (beef & pork), Poultry, Seafood, Bakery, Snack Food (pretzels, potato chips, tortilla chips), Fruits & Vegetables Non-food Industry: Automotive, Tire Manufacturing, Packaging, Printing/Paper, Postal Services, Corrugated Cardboard, Can Manufacturing, PET Manufacturing, Textile |

| Advantages | Maintenance-free, easy to clean, big load capability, and significantly longer life compared to traditional conveyor belts. Environmentally friendly with reduced pollution. |

Additional Information

To ensure consistent availability, we maintain a stock of various raw materials. Our advanced processing workshop spans 30,000 square meters with 50 sets of injection molding machines, facilitating swift production times.