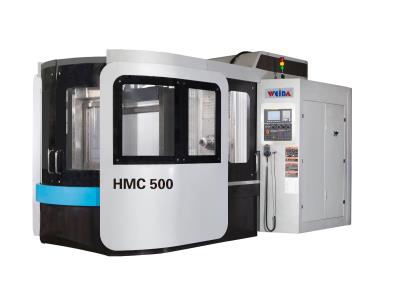

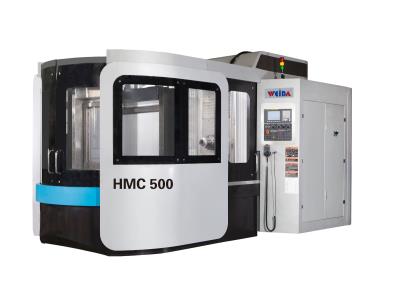

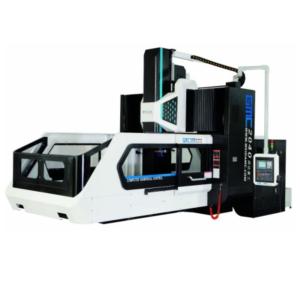

OEM ODM HORIZONTAL MACHINING CENTER HMC500

Description

The Horizontal Machining Center HMC500 is a state-of-the-art machining solution designed for precision engineering. It boasts a robust configuration featuring a Fanuc 0i F Plus 5 control system, ensuring high accuracy and reliability. The machine is equipped with a Taiwan PARKSON single rotary table, capable of supporting complex machining tasks with ease. The HMC500 includes a high-speed CELLS 6000rpm belt type BT50 spindle, enhancing its performance in various machining applications.

Engineered with Taiwan Hiwin linear guides and ballscrews, along with a Taiwan Stairs pump, this machining center ensures smooth operation and reduced wear over time. The arm-type tool magazine accommodates 24 tools, enabling efficient tool changes to maximize productivity. The HMC500 is also designed with features such as automatic central lubrication, electrical handwheel, and dual chip conveyors to streamline the machining process. With advanced tooling capabilities and a comprehensive set of specifications, the HMC500 is the perfect choice for industries requiring high precision and efficiency.

Specifications

| Item | Unit | Value |

|---|---|---|

| Table Size | mm | 500×500 |

| Table Numbers | pc | 1 |

| Max Load of Table | kg | 500 |

| T Slot | 5-14-100 | |

| Table Indexing | 1°x360° | |

| Travel (X,Y,Z) | mm | 800/650/800 |

| Max Workpiece Diameter | mm | 800 |

| Distance from Spindle Axis to Table Surface | mm | 100-750 |

| Distance from Table Center to Spindle Nose | mm | 150-950 |

| Spindle Taper | BT50 | |

| Spindle Speed | rpm | 3000 |

| Spindle Rating Torque | N.M | 235 |

| Main Motor Power | KW | 15/18.5 |

| Max Drilling Diameter | mm | 50 |

| Max Tapping Diameter (Casting) | mm | M24 |

| Max Tapping Diameter (Steel) | mm | M20 |

| Cutting Feed | mm/min | 1-12000 |

| Rapid Speed | mm/min | 32000 |

| Machine Overall Dimensions | mm | 5600x3200x2900 (L*W*H) |

| Machine Net Weight | kg | 10,000 |

Additional Information

The Horizontal Machining Center HMC500 is ideal for various machining applications, providing high precision and reliability. Its robust design and advanced features make it suitable for industries such as aerospace, automotive, and general manufacturing. Regular maintenance and adherence to operating guidelines will ensure optimal performance and longevity of the machine.