Description

The HORIZONTAL MACHINING CENTERS HF400 is engineered for precision and efficiency, featuring a robust T-type layout machine base that ensures structural rigidity and stability during operation. This sophisticated machine is equipped with imported high-rigidity lead screws, guide rails, and couplers, promoting exceptional stability and precision. Its spindle is supported by high-speed and precise NSK angular contact ball bearings, ensuring low temperature rise and maintenance-free operation. The HF400 boasts a specialized high overload and high-speed variable frequency motor, providing excellent output torque to tackle demanding machining tasks. Designed for durability, it incorporates a full protection structure that prevents chips and coolant from splashing, while high torque feed servo motors on all three axes enhance performance. The electric cabinet is equipped with a heat exchange system, conforming to EU safety standards and making it suitable for export.

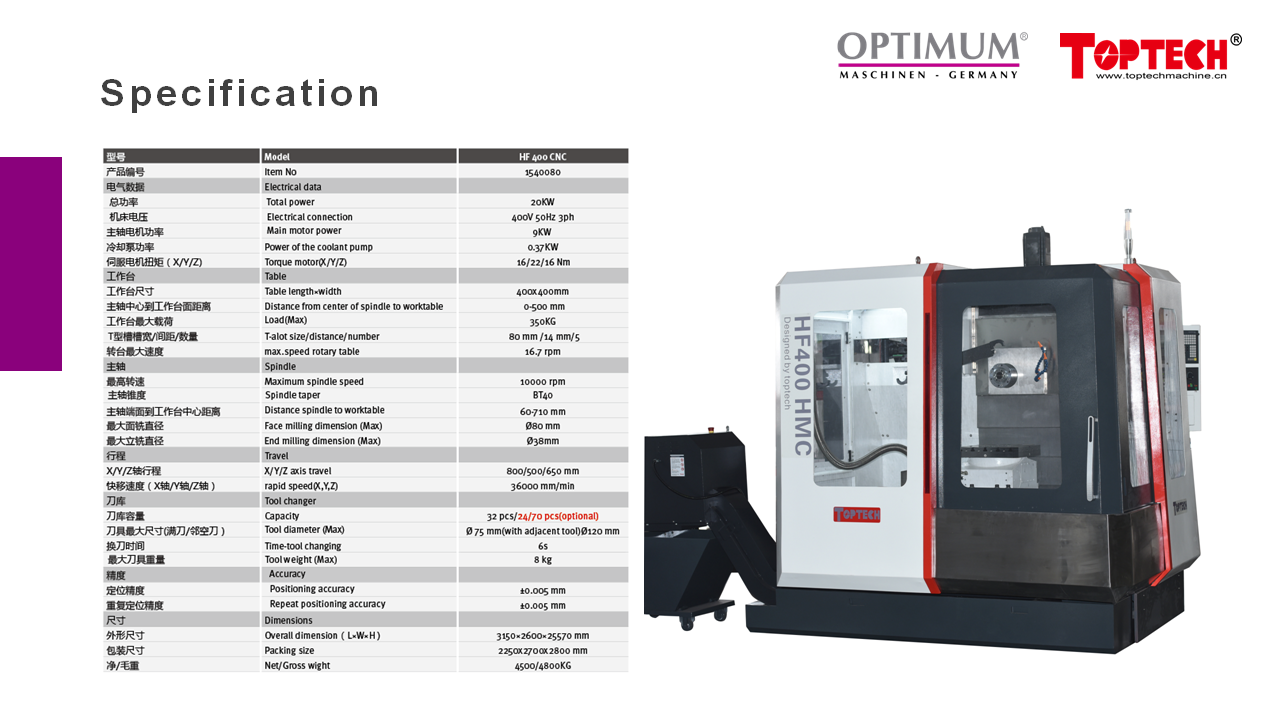

Specifications

| Feature | Description |

|---|---|

| Layout | T-type layout machine base |

| Moving Parts | Imported high rigidity lead screw, guide rail, and coupler |

| Spindle Bearings | High speed & precision NSK angular contact ball bearings |

| Lubrication | High speed lithium-based grease |

| Motor Type | High overload & high-speed variable frequency motor |

| Protection | Full protection structure against chips and coolant |

| Servo Motors | High torque feed servo motors on all three axes |

| Electric Cabinet | Equipped with heat exchange system |

| Compliance | EU safety standards (suitable for export) |

Additional Information

The HORIZONTAL MACHINING CENTERS HF400 is perfect for industries requiring high precision machining solutions. Its robust design and advanced technology make it a reliable choice for various applications.