Description

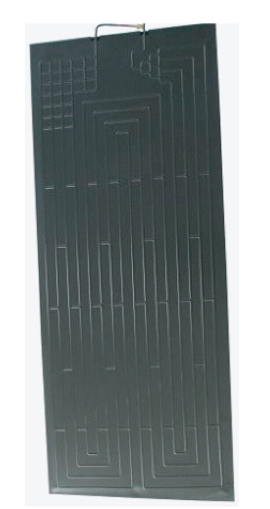

Introducing the Hot Water Heater Thermodynamic Solar Panel, an innovative solution designed for efficient hot water heating systems. This advanced thermodynamic solar panel utilizes a roll bond structure, ensuring optimal performance and durability. Crafted from high-quality aluminum plates, this panel is engineered to withstand harsh conditions while providing reliable heating for residential and commercial applications.

Featuring a double side roll bond evaporator, the panel is capable of producing hot water efficiently, making it an ideal choice for heat pumps. Its surface is treated with a protective powder coating to prevent corrosion, ensuring longevity and reliability. The inner cleanliness meets stringent requirements for R134A and CFC cooling systems, highlighting its suitability for various cooling applications.

Specifications

| Attribute | Details |

|---|---|

| Raw Material | Al-plate |

| Finished Product Thickness | 1.1 – 2.0 mm |

| Raw Material Al Plate Thickness | 1.4 – 2.5 mm |

| Coating Thickness | 40 – 90 μm |

| Coating Hardness | More than 2H |

| Maximum Width | 590 mm |

| Maximum Length | 2050 mm |

Additional Information

This thermodynamic solar panel is widely applicable across various appliances, including refrigerators, freezers, showcases, water dispensers, and wine cabinets. It is designed to meet high-performance standards, producing up to 3.5 million sets annually, ensuring a steady supply for your heating needs.