Description

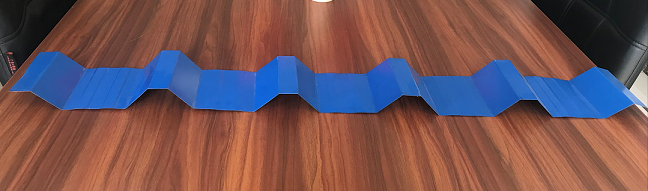

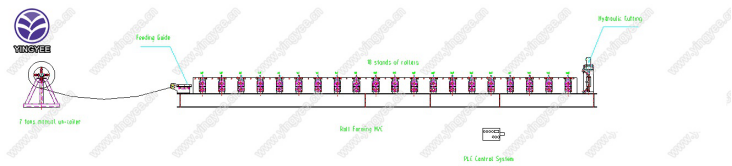

The IBR/trapezoid roof sheet roll forming machine is a high-efficiency solution designed for producing high-quality roof sheets at a speed of 15 meters per minute. Engineered with precision, this machine is capable of processing a variety of materials including PPGI, GI, and aluminum, making it versatile for different applications. Its robust construction and advanced features ensure durability and optimal performance in any manufacturing environment.

This machine includes a comprehensive set of components such as a coiler, adjustable input equipment, a main roll forming machine with chromed plates, a hydraulic cutting system, a hydraulic station, and a PLC control system. The innovative design ensures ease of use and high productivity.

Specifications

| Attribute | Details |

|---|---|

| Matching Material | PPGI/GI/Aluminium |

| Material Thickness | 0.2-0.8 mm |

| Power | 5.5 kW |

| Forming Speed | 15 m/min |

| Width of Plates | According to the drawings |

| Input Leveling Equipment | Adjustable |

| Roll Stations | 13 |

| Shaft Material and Diameter | 45# Steel, Ø75 mm |

| Tolerance | 10 m ± 1.5 mm |

| Drive Method | Chain driven |

| Controlling System | PLC |

| Voltage | Depends on client |

| Material of Forming Rollers | 45# Steel, heat treatment and chromed |

| Side Plate | Steel plate with chromed |

| Size | Length: 6.7 m, Weight: 5 tons |

Additional Information

- The machine is designed for easy operation and maintenance.

- Adjust the input leveling equipment according to specific manufacturing needs.