Description

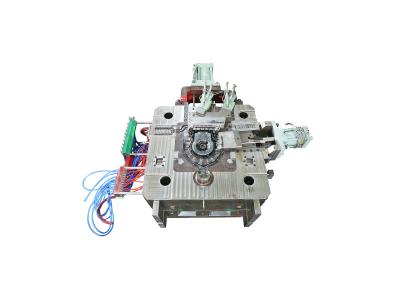

The injection mold is a precision-engineered tool designed for creating high-quality plastic parts through the injection molding process. This robust mold is manufactured by experienced professionals, ensuring exceptional craftsmanship and reliability. With capabilities to produce complex shapes and high-precision designs, it meets the demands of various industries, including automotive, electronics, and home appliances. The mold offers a customizable solution tailored to specific production needs, making it an ideal choice for businesses seeking efficiency and quality.

Specifications

| Attribute | Details |

|---|---|

| Manufacturer | FOSHAN SYMBOS PRECISION MOULD. CO.,LTD |

| Design Software | UG, Pro-E, AutoCAD, CATIA |

| Installation | Fixed |

| Runner | Cold/Hot Runner (YUDO, HRS, Moldmaster, HUSKY, DME, local brands, etc.) |

| Standard | LKM/HASCO/DME/FUTA, etc. |

| Cavity | Single/Multiple Cavities |

| Mould Base | P20, 45#, 4CR13, etc. |

| Mould Life | 0.2-2 million shots |

| Mould Material | P20, P20H, 718, 718H, 2738, Nak80, S136, SKD61, 8407, H13, 2343, 2344, 2311, 2312, 2379, 2316, 2093, 2767, etc. |

| Surface Treatment | Heat treatment, polishing, texture, coating, etc. |

| Gate Types | Side gate, edge gate, submarine, pin point, horn, direct gate, capillary, etc. |

| Tonnage | 50-3600T |

| T1 Time | 30-40 days |

| Specification | Customized |

| Transport Package | Plastic bag/Carton box/Wooden Case |

| HS Code | 8480719090 |

| Industries Served | Automotive, Communications, Electronics, Home Appliances, Household Products, etc. |

Our Advantages

| 1) | Around 20 years of mold-making experience, certified with ISO 9001 & IATF 16949, with skilled professional workers, excelling in strong engineering, exquisite workmanship, and complex shapes. |

| 2) | More than 30 countries’ export experience ensures our technical team can offer tailor-made services to meet international standards. |

| 3) | We invest significantly in hardware and software facilities, possessing advanced and high-precision equipment along with the latest mold design software. |

| 4) | Collaboration with world-class Japanese brands, ensuring rigorous management and quality control systems, leading to high industry standards. |

| 5) | Direct manufacturer and exporter, ensuring cost-effectiveness, with some mature molds being 20-30% cheaper than competitors. |

| 6) | Three factories guarantee ample production capacity, short lead times, and quick response capabilities. |

| 7) | Expertise in material selection to ensure long lifespan and excellent hot runner and cooling systems, enhancing production efficiency. |