Description

The AF Series Double Linear Motion Guide Injection Molding Machine is a cutting-edge solution for precise plastic injection. Engineered with a fast and reliable linear motion system, it integrates a servo control energy-saving system, ensuring optimal performance and efficiency. This machine is designed to deliver superior injection quality, catering to a variety of applications in the manufacturing sector.

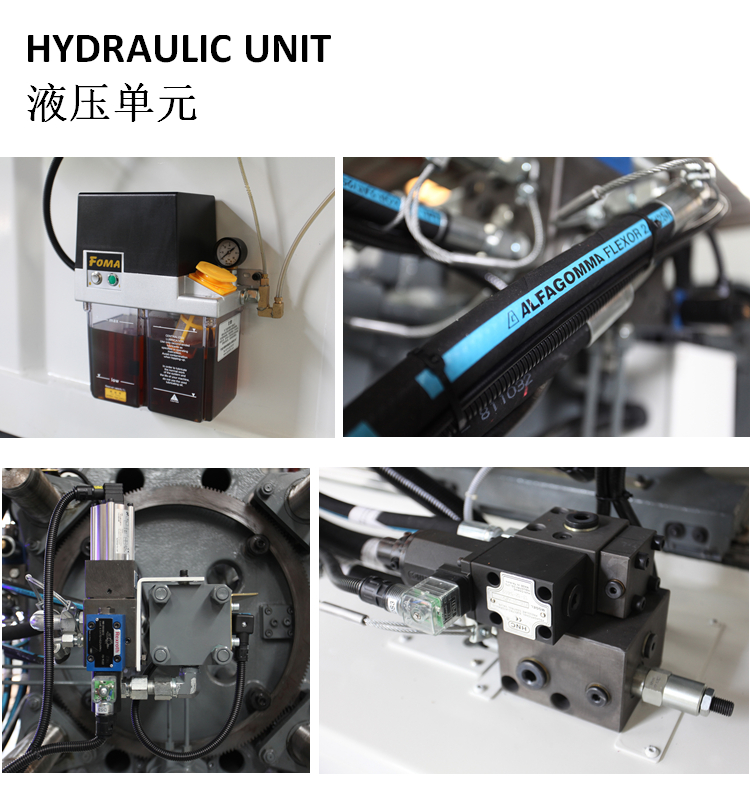

Equipped with advanced clamping and injection units, the AF Series features an optimized platen design for enhanced rigidity, a new ejection system for improved stroke and space, and a hydraulic-driven gear-type mold height adjustment mechanism. The machine’s hydraulic system utilizes a double proportional compound valve for precise pressure and flow control, while the electrical system boasts high-speed control with a user-friendly interface.

Specifications

| Feature | Description |

|---|---|

| Clamping Unit | Optimized platen design, Euromap-based layout, new ejection system, hydraulic adjustment mechanism, and enhanced rigidity. |

| Injection Unit | High-quality linear motion guide, high-speed injection structure, twin nozzle cylinder, specialized screw barrel design. |

| Hydraulic System | Double proportional compound valve control, imported high-quality pump, optional servo hydraulic system, low-pressure mold protection, independent lubrication system. |

| Electrical System | Double CPU control, 8.4″ display, USB and ethernet ports, 32 input/output points, high precision control. |

| Servo Controller | High precise control, fast response time, low noise, energy-saving capabilities, and water cooling efficiency. |

Additional Information

For optimal performance, it is recommended to conduct regular maintenance and ensure proper lubrication of all moving parts. This injection molding machine is designed for high efficiency and low noise, making it suitable for use in cleanroom environments.