Description

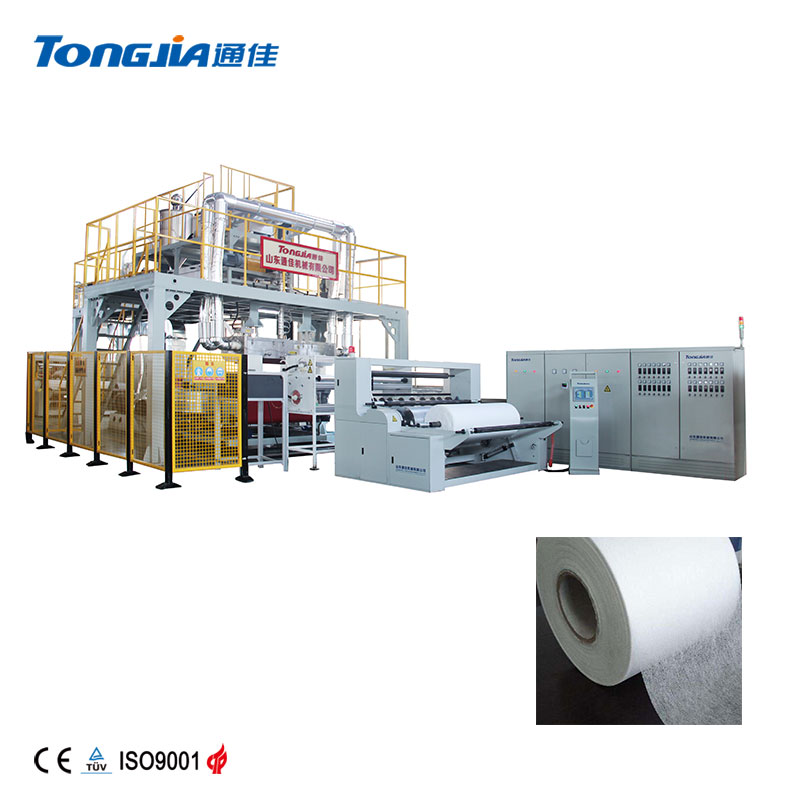

The JG-RPB1600PP meltblown non-woven production line is engineered for stability and reliability, creating high-quality meltblown non-woven materials with excellent air permeability. This production line is essential for a variety of applications, including medical protective masks, automotive air filters, water purifier filters, and disposable cleaning supplies. Its advanced technology ensures that the fabric is evenly laid, maximizing efficiency and product performance.

Specifications

| Attribute | Model JG-RPB1600M | Model JG-RPB2400M | Model JG-RPB3200M |

|---|---|---|---|

| Width | 1.6 M | 2.4 M | 3.2 M |

| Gram range | 16-200 G/M² | 16-200 G/M² | 16-200 G/M² |

| Production capacity | 1.6-2 Ton | 2.5-3 Ton | 3-4 Ton |

| Speed | <50 m/min | <50 m/min | <50 m/min |

| Power consumption | 3000 – 3800 °/Ton | 3000 – 4000 °/Ton | 3200 – 4200 °/Ton |

| Dimensions (approx.) | 20×6×6 M | 22×8×6 M | 25×8×6 M |

Additional Information

Features and Uses of Meltblown Non-Woven Fabric:

- High filtration efficiency and low resistance.

- Soft texture and self-bonding ability.

- Used in air filtration, food sanitary filtration, and industrial dust mask making.

Common Application Areas:

- Air Purification: Used in air purifiers and filters, offering small resistance and excellent durability.

- Medical and Health: Dust-proof masks with over 95% efficiency for various health applications.

- Liquid Filtration: Cost-effective battery separators and filter materials.

- Oil-Absorbing Materials: Utilized in environmental protection and industrial cleaning.

- Thermal Insulation: Effective in clothing and insulation materials, offering lightweight warmth and breathability.