Description

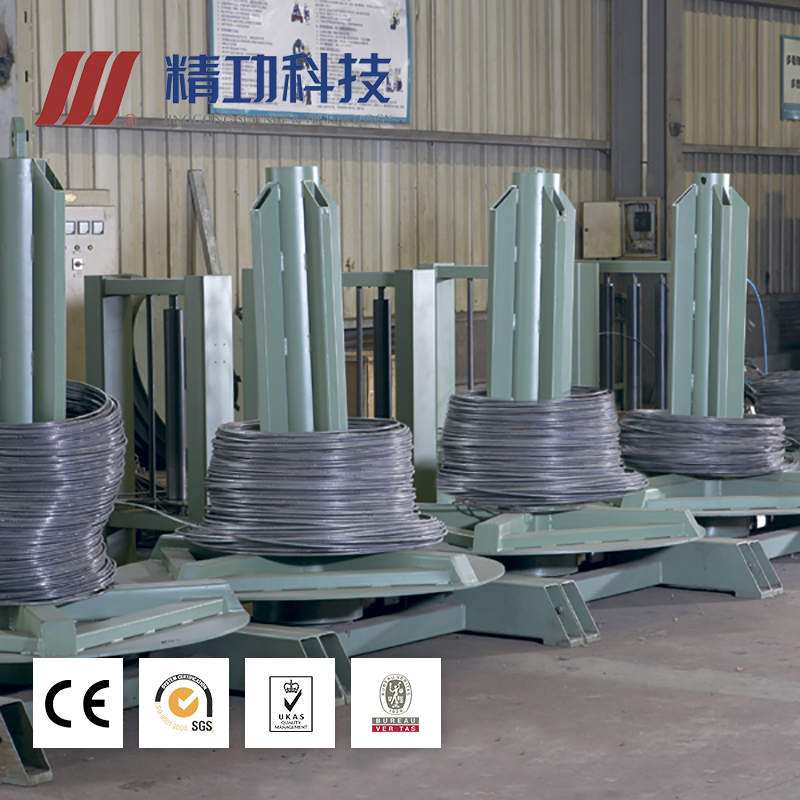

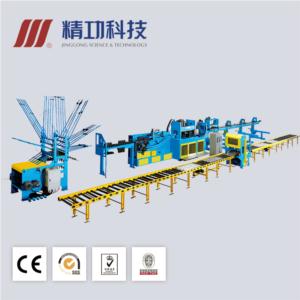

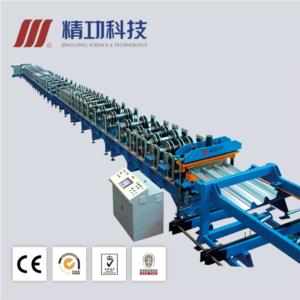

The JGH self-supported steel deck whole set production line is an advanced manufacturing solution developed by Zhejiang Jinggong Science & Technology Co. Ltd. This innovative system combines a truss welding line, bottom panel forming machine, and board spot welding machine into a cohesive unit. Utilizing mechanisms that integrate electricity, hydraulics, and pneumatics, all controlled by a microcomputer, this production line efficiently manages the entire process of steel molding board fabrication, including truss formation, galvanized steel shaping, and assembly welding.

Designed specifically for the steel construction industry, the self-supported steel deck panel has emerged as a revolutionary building material. With an annual production capacity of up to 300,000 square meters, it is ideal for applications in structural floor decks, bridges, railways, and more. Its lightweight construction and high strength make it a preferred choice, while the efficient pouring of concrete onto the steel deck significantly reduces site workload and shortens construction timelines.

Specifications

| Feature | Details |

|---|---|

| Annual Production Capacity | 300,000 square meters |

| Components | Truss welding line, bottom panel forming machine, board spot welding machine |

| Control System | Microcomputer control |

| Main Application | Steel structural floor decks, bridges, railways |

| Construction Advantages | Light structure, high strength, reduced site workload |

Additional Information

- Utilizes advanced integration of mechanisms for optimal performance.

- Shortens construction periods significantly through efficient processes.

- Widely accepted in various construction applications due to its reliability and efficiency.