Description

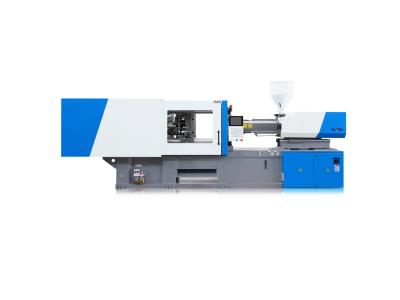

The K series Servo Energy-saving Injection Molding Machine is a state-of-the-art solution designed for high precision and efficiency in plastic injection molding. Developed by Italian engineers, this machine seamlessly integrates renowned electrical components and a servo motor, making it ideal for producing a wide range of applications, particularly in the automotive and other precise industrial sectors. This European-style model showcases a robust design with features that enhance stability and reliability.

Key Features:

- T-groove and screw hole integration in the formwork for improved function.

- Wide plate large modulus design for enhanced durability.

- Stable movement facilitated by an increased contacting area and longer guide distance of the moving platen.

- Reliable safety features including international-standard circuit breakers and sensitive temperature controls.

- Spacious servo electric cabinet that ensures effective heat dissipation.

- European standard industrial interface offers safety and reliability.

- Customization options available for specialized applications such as PVC and PET preforms, or buckets.

Specifications

| Item | Model | K110-SA | K150-SA | K180-SA | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| International Rating Size | 350 | 430 | 600 | |||||||

| Screw Type | A | B | C | A | B | C | A | B | C | |

| Screw Diameter | mm | 32 | 36 | 40 | 36 | 40 | 45 | 40 | 45 | 50 |

| Screw L:D Ratio | 22.5 | 20.0 | 18.0 | 22.2 | 20.0 | 17.8 | 22.5 | 20.0 | 18.0 | |

| Shot Volume | cm³ | 145 | 183 | 226 | 204 | 251 | 318 | 283 | 358 | 442 |

| Shot Weight (PS) | g | 132 | 167 | 206 | 185 | 229 | 289 | 257 | 326 | 402 |

| Injection Pressure | Bar | 2393 | 1890 | 1531 | 2154 | 1745 | 1378 | 2231 | 1763 | 1428 |

| Injection Rate | cm³/s | 81 | 102 | 126 | 106 | 130 | 165 | 126 | 159 | 196 |

| Plasticizing Capacity | g/s | 8 | 12 | 19 | 11 | 17 | 22 | 16 | 22 | 26 |

| Max. Screw Speed | r/min | 220 | 195 | 190 | ||||||

| Clamping Force | kN | 1100 | 1500 | 1800 | ||||||

| Space Between Tie Bars | mm | 410×360 | 460×410 | 520×470 | ||||||

| Platens Size | mm | 590×540 | 660×610 | 740×690 | ||||||

| Opening Stroke | mm | 350 | 400 | 460 | ||||||

| Min. Mold Height | mm | 170 | 200 | 200 | ||||||

| Max. Mold Height | mm | 420 | 510 | 550 | ||||||

| Distance Between Platens (Daylight) | mm | 770 | 910 | 1010 | ||||||

| Ejector Stroke | mm | 110 | 130 | 130 | ||||||

| Ejector Force | kN | 40 | 40 | 50 | ||||||

| Number of Ejector | 5 | 5 | 5 | |||||||

| System Pressure | Bar | 175 | 175 | 175 | ||||||

| Pump Motor Power | Kw | 13 | 16 | 20 | ||||||

| Heating Power | Kw | 6.3 | 7.5 | 10.0 | ||||||

| Oil Tank Capacity | L | 150 | 150 | 200 | ||||||

| Machine Dimension (L×W×H) | m×m×m | 4.6×1.2×1.9 | 4.8×1.2×1.9 | 5.2×1.3×2.1 | ||||||

| Machine Weight | t | 3.6 | 4.4 | 6 | ||||||

| Hopper Capacity | kg | 25 | 25 | 25 | ||||||