Description

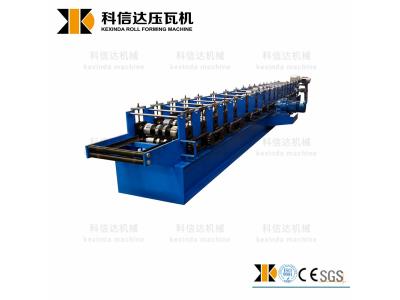

The Kexinda Hose Crimping Machine is a robust and reliable solution designed for the efficient processing of welded pipes. This advanced machine operates under the control of a gear wheel oil pump, ensuring precise cutting operations once hydraulic oil fills the tank. The system is comprehensive, comprising a hydraulic tank, oil pump, hydraulic pipes, and electromagnetism valves, all designed for optimal functionality in pipe manufacturing.

This machine is capable of processing various materials, specifically galvanized iron (GI) and pre-painted galvanized iron (PPGI), with a plate thickness ranging from 0.3mm to 0.8mm. Its productivity rate is impressive, achieving speeds of 8 to 15 meters per minute, making it an efficient choice for industrial applications.

Specifications

| Attribute | Details |

|---|---|

| Suitable Material to Process | GI & PPGI |

| Thickness of Plate | 0.3 – 0.8 mm |

| Productivity | 8 – 15 m/min |

| Rollers | 23 rows |

| Diameter of the Roller | 56 mm |

| Dimensions (Major Structure) | 10 x 1.2 x 1 m |

Additional Information

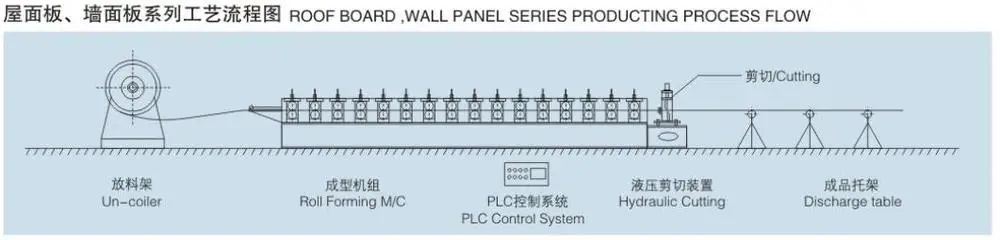

The machine features a man-made uncoiler, roll forming machine, PLC system, hydraulic system, blade, and receiving table, all contributing to its efficient operation. The uncoiler can bear up to 3 tons and is suitable for coiled steel with an inside diameter of 508mm. The system is equipped with a computer control cabinet that utilizes Panasonic technology, allowing for easy adjustments of the target piece’s length in both automatic and manual modes.

For optimal performance and maintenance, it is recommended to adhere to the equipment regulations and ensure the proper feeding of raw materials onto the platform for uniform processing.