Description

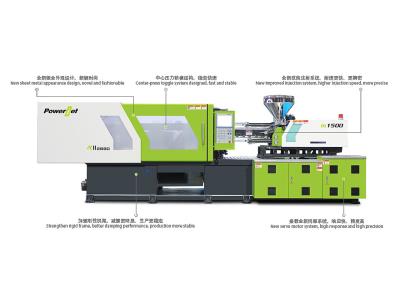

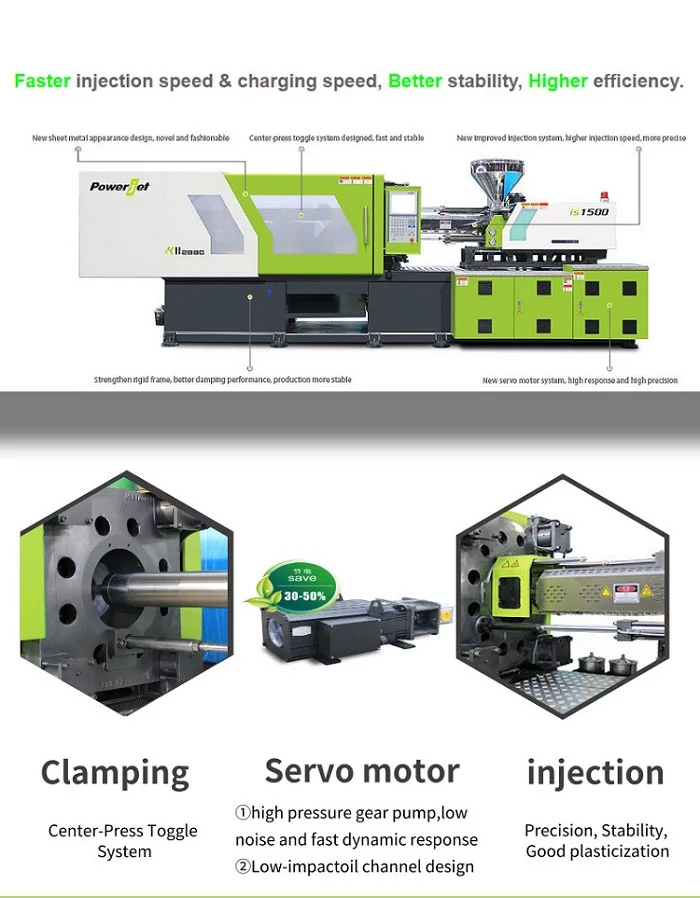

The KII Series High Precision Injection Molding Machine is engineered to deliver exceptional performance in the manufacturing sector. With its advanced hydraulic driving system and servo motor technology, this machine boasts faster injection and plasticizing speeds, ensuring a higher efficiency and stable operation. Designed for versatility, it excels in producing a wide range of products, including food and beverage packaging, household necessities, home appliances, electrical components, and automotive parts.

Specifications

| Unit | Specification |

|---|---|

| Clamping Force | 900~10000 (KN) |

| Driving System | Hydraulic |

| Motor Type | Servo |

| Applications | Food and Beverage Packaging, Necessities Products, Home Appliances, Electrical Components, Automotive Parts |

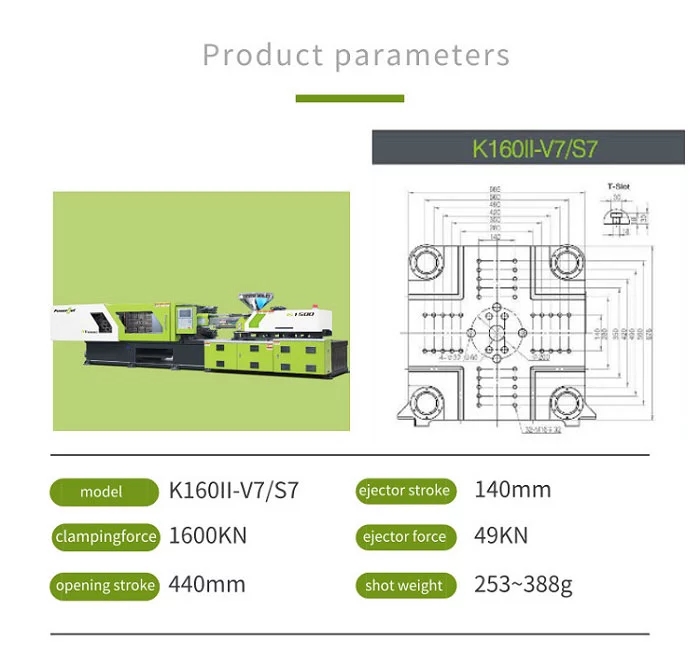

| LAMPING UNIT | Specification | Unit |

|---|---|---|

| Clamping Force | 2880 | KN |

| Opening Stroke | 550 | mm |

| Max. Daylight | 1160 | mm |

| Platen Size | 850*850 | mm |

| Space Between Bars | 610*610 | mm |

| Max. Mold Height | 610 | mm |

| Min. Mold Height | 280 | mm |

| Ejector Stroke | 150 | mm |

| Ejector Force | 77 | KN |

| INJECTION UNIT | Specification | Unit |

|---|---|---|

| Screw Diameter | 68 | mm |

| Screw L/D Ratio | 19 | L/D |

| Injection Pressure | 145 | MPa |

| Shot Volume | 1017 | cm³ |

| Shot Weight (ps) | 905 | g |

| Injection Rate | 402 | g/s |

| Screw Stroke | 280 | mm |

| Screw Speed | 236 | rpm |

| POWER UNIT | Specification | Unit |

|---|---|---|

| Hydraulic System Pressure | 17.5 | MPa |

| Pump Motor Power | 30/53.3 | KW |

| Heater Power | 13.8 | KW |

| GENERAL | Specification | Unit |

|---|---|---|

| Oil Tank Capacity | 400 | L |

| Machine Weight | 9.7 | T |

| Machine Dimensions (L*W*H) | 6.1*1.61*1.85 | m |

Additional Information

The KII Series injection molding machine is designed for a wide range of applications, ensuring that it meets the diverse needs of modern manufacturing. Its robust features and efficient design make it an excellent choice for businesses looking to enhance their production capabilities.