Description

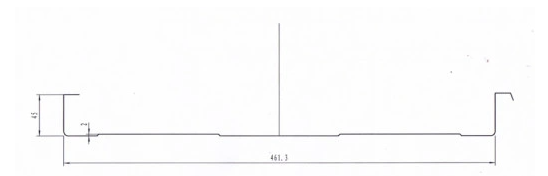

The KR Metal Tile Roofing Roll Forming Machine is a high-performance solution designed for the efficient production of metal roofing tiles. Renowned for its durability and precision, this advanced machine integrates a robust chassis made of 250mm U-steel structural steel to withstand rigorous operations. Engineered to meet the evolving needs of the metal roofing industry, it offers exceptional forming speeds of 8-15m/min and a versatility that allows production across a range of tile styles.

The machine features a user-friendly PLC control system with a touch screen interface, ensuring seamless operation and monitoring. With components manufactured in-house, the KR Metal Tile Roofing Machine guarantees quality and cost-effectiveness without compromising on safety standards required for export. The machine’s technical prowess is evidenced by its 12-step forming rollers and high-quality materials, including 45# steel coated with hard chrome for longevity and efficiency.

This machine is backed by a professional engineering team that provides design assistance and overseas technical guidance, ensuring customer satisfaction and operational excellence.

Specifications

| Parameter | Value |

|---|---|

| Chassis | 250mm U-steel structural steel welding |

| Forming Type | Chain drive |

| Axle Diameter | 65mm |

| Chain | 16A |

| Forming Motor Power | 5.5kw |

| Forming Speed | 8-15m/min |

| Forming Rollers | 12 steps |

| Roller Material | 45# steel, coated hard chrome |

| Hard Chrome Thickness | 0.05mm |

| Hydraulic Station Motor | 3kw |

| Hydraulic Oil Pump | Gear pump |

| Cutting Type | Hydroform cutter |

| Cutting Material | Cr12, heat treatment HRC58° -60° |

| Coil Thickness | 0.5-1.3mm |

| Length Scale Precision | ± 2mm |

| Transducer | YASKAWA |

| Control System | PLC, touch screen |

| Power Supply | 220V 60Hz 3 phase, 15KW electric generator |

| Size | 5500mm x 1500mm x 2000mm |

| Weight | 5 tons |

Additional Information

The KR Metal Tile Roofing Roll Forming Machine comes with a comprehensive set of tools to facilitate operations, including:

- Decoiler: 1 unit

- Sewing Machines: 2 units

- Collection Table: 1 unit

- Clamps: 4 units

- Bearing (208#): 4 units

- Drive Chain: 3 units (run)

- Chain Links: 3 units

- Half-sections: 3 units

- Super Pliers: 1 unit

- Metal Scissors: 1 unit

- Wrench: 1 unit

- Travel Switch: 1 set