Description

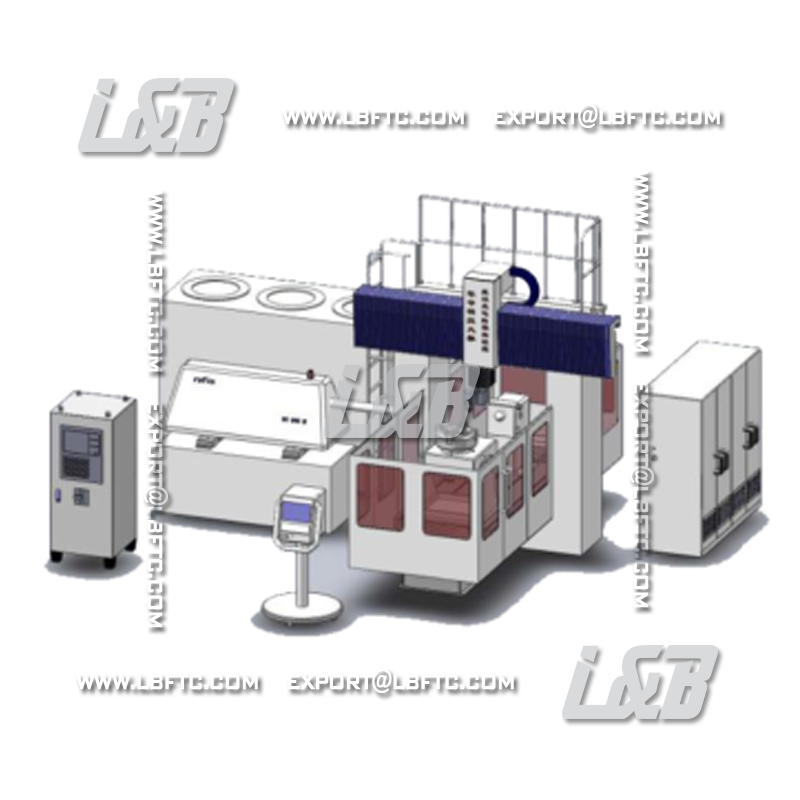

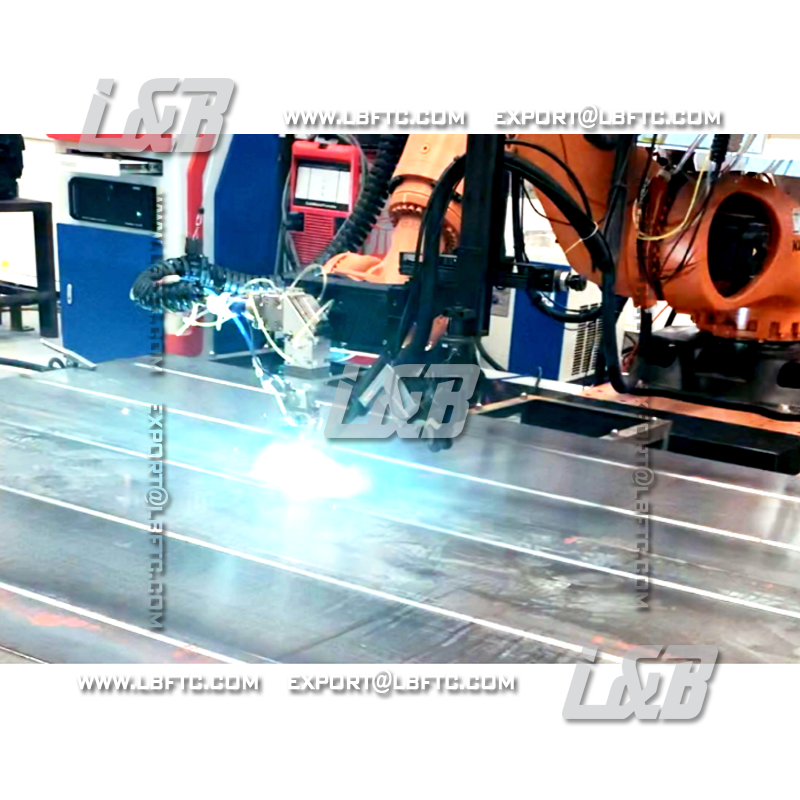

The Laser-arc Hybrid Welding Automatic Machine is designed to meet the demands of fast and high-precision welding for small batches and various structural products. This advanced machine effectively addresses technical challenges such as poor consistency and subpar welding mechanical properties that often arise from large welding gaps. Its efficient and straightforward tooling fixture design allows for the welding of large and complex structural parts with ease. Featuring a powerful laser welding and laser-arc composite welding process system, this machine is capable of processing a wide array of materials, including low-alloy high-strength steel, stainless steel, light metals like magnesium, aluminum, and titanium, as well as difficult-to-weld materials such as red copper, high-temperature alloys, and dissimilar metals. The result is high-quality welding that ensures durability and reliability. With strong expansion capabilities and excellent operability, this machine provides the flexibility for future function enhancements and process support.

Specifications

| Attribute | Details |

|---|---|

| Welding Process | Laser-arc Hybrid Welding |

| Materials Processed | Low-alloy high-strength steel, Stainless steel, Light metals (magnesium, aluminum, titanium), Red copper, High-temperature alloys, Dissimilar metals |

| Welding Capability | High precision for small batches |

| Tooling Fixture Design | Efficient and simple for complex structural parts |

| Expansion Capability | Strong with good operability |