Description

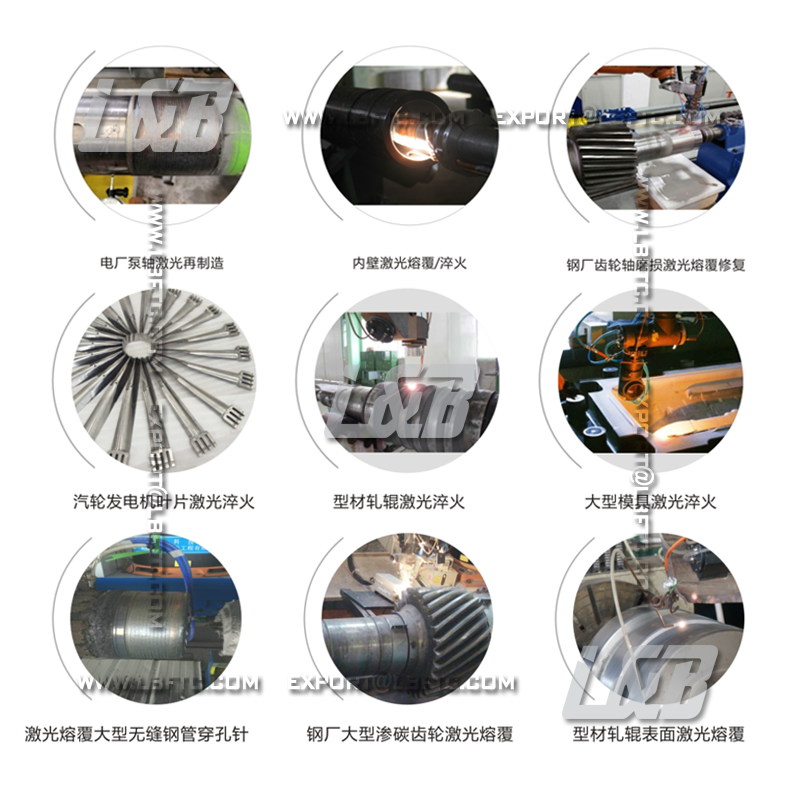

Laser Quenching Hardening Processing Equipment is a state-of-the-art solution designed to enhance the durability of metal components through advanced laser cladding technology. This innovative system utilizes a high-energy-density laser beam to heat the surface of metal materials, enabling a solid phase transition and facilitating a rapid fusion cladding process. As a result, the equipment significantly improves the wear resistance, corrosion resistance, and oxidation resistance of the material surfaces. Additionally, it allows for the repair of surface shapes or sizes of parts, making it an essential tool in various industrial applications.

The equipment boasts several technical advantages, including:

- High-performance imported lasers and efficient composite cladding actuators.

- Precision servo drive system for enhanced reliability and rapid response.

- Unique optical transmission system with lens water cooling and positive pressure protection, ensuring stability and anti-interference capabilities.

- Comprehensive process data parameters for simple operation.

- Automatic powder feeder for laser cladding.

This equipment is not only efficient but also versatile, capable of achieving high energy density with minimal deformation of the workpiece. The heating layer’s depth and position can be accurately controlled, extending the service life of processed workpieces by three times.

Specifications

| Feature | Details |

|---|---|

| Laser Type | Imported high-energy-density laser |

| Drive System | Precision servo drive |

| Cooling System | Lens water cooling |

| Protection Features | Positive pressure protection device |

| Processing Thickness | Wide, with single or multiple layers |

| Operation | Simple with complete process data parameters |