Description

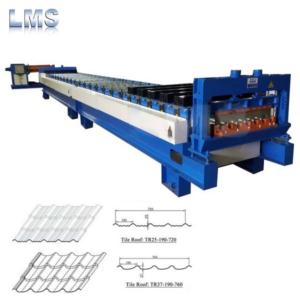

The LMS Step Tile Roof Roll Forming Machine is a state-of-the-art solution designed for efficient and precise roll forming of step tile roofs. With over 40 years of experience in roll forming machinery, this robust machine ensures high-quality production through its advanced features. It is equipped with a hydraulic decoiler and a manual shearer, allowing for seamless operation and precise length control via a user-friendly touch screen interface. The machine is built using refined steel plates, ensuring durability and strength, while the use of 18 to 24 rollers guarantees the integrity of the formed profiles. With Mitsubishi PLC technology and a precise servo motor, this machine minimizes tolerance, making it an ideal choice for any roofing project.

Specifications

| Attribute | Details |

|---|---|

| Suitable Material | PPGI Coil / Embossed Aluminium Coil |

| Material Width | 914 / 1000 / 1220 / 1250 mm |

| Material Thickness | 0.40 — 0.80 mm |

| Hydraulic Decoiler | 10 tons, 1250 mm width, 500 – 600 mm inner diameter, 4.0 kW |

| Roll Forming Machine | 18 – 24 roller stations, 80 mm main shaft, 22 – 25 mm sidewall thickness, 5 kW servo motor, 3 – 10 m/min speed |

| Hydraulic Step Forming & Cutting-off | 10 tons working table pressure, with fan-cooler, 7.5 kW |

| PLC Controller | Mitsubishi PLC, 5.7″ touch screen, Japanese frequency converter, Schneider electronic components |

Additional Information

The production process includes decoiling, manual shearing, roll forming, step forming, cutting-off after sizing, and final step tile creation. This comprehensive approach ensures that every tile produced meets high standards of quality and precision.