Description

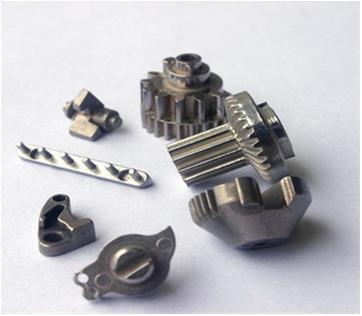

Metal Injection Molding (MIM) is a cutting-edge manufacturing process that combines the versatility of plastic injection molding with the strength and integrity of metal fabrication. This technique allows for the production of complex metal parts with high precision and repeatability, making it an ideal choice for various applications. MIM is particularly well-suited for industries that require intricate shapes and tight tolerances, without compromising on quality.

Application Areas of Metal Injection Molding:

- Car Parts: Essential components for automotive applications, providing durability and performance.

- Medical Instrument Parts: Precision parts for medical devices, ensuring safety and reliability.

- Hardware Tools: Robust tools that stand the test of time, designed for functionality.

- 3C Industry Parts: High-quality components for consumer electronics and related sectors.

Specifications

| Feature | Description |

|---|---|

| Process | Metal Injection Molding |

| Materials | Variety of metals suitable for injection molding |

| Applications | Car parts, medical instruments, hardware tools, 3C industry parts |

Additional Information

Metal Injection Molding offers an efficient solution for manufacturing complex parts with reduced waste and enhanced production rates. This method not only improves design flexibility but also lowers overall manufacturing costs, making it a preferred choice in many industries.