Description

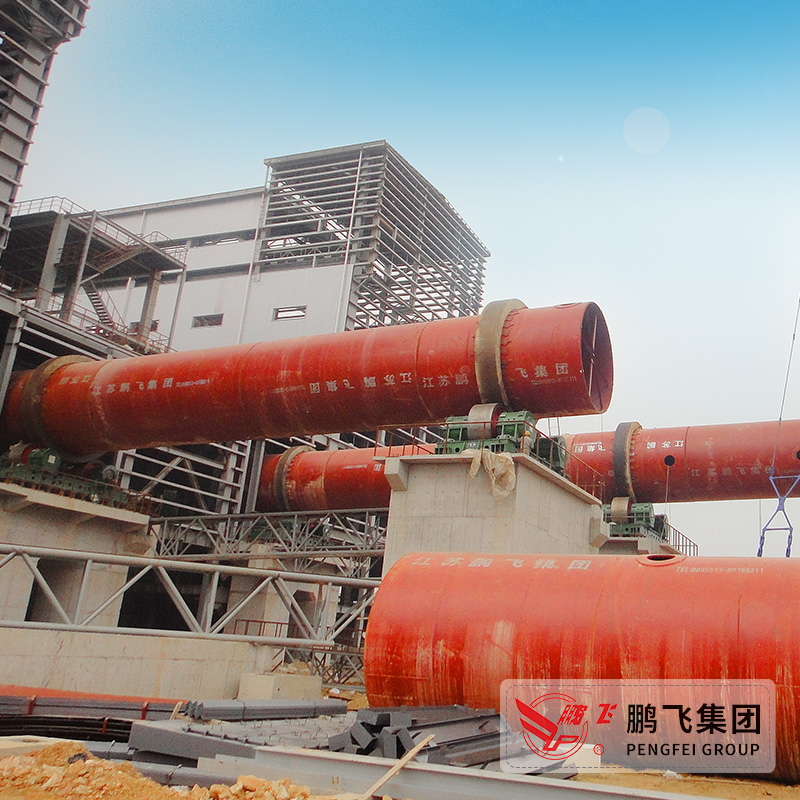

This metallurgical rotary kiln is a cutting-edge, large-size calcining kiln developed in collaboration with esteemed scientific research institutes. It represents advanced technology in metallurgy, ensuring a remarkable 30% increase in production capacity while reducing heat consumption by 40%. With a discharged flue gas temperature of less than 250℃, this kiln is designed to facilitate efficient dust collection and adhere to modern environmental protection standards focused on energy saving and consumption reduction. It is widely utilized in various applications, including nickel extraction from laterite, calcining activated limestone, and processing of oxidized pellets, magnesium oxide, aluminum oxide, and titanium dioxide.

Key features include:

- The rotary kiln cylinder is engineered to minimize deflection, thereby extending the lifespan of refractory bricks and castable materials.

- Utilizes large diameter, smaller aspect ratio supporting roller bearings that enhance reliability, featuring self-aligning capabilities.

- Innovative open gear wheel cover sealing ensures excellent sealing performance.

- Equipped with spring overlying flexible sealing, which includes a double spring mechanism that adds an insulation layer, improving both reliability and lifespan.

Specifications

| Attribute | Details |

|---|---|

| Production Capacity Increase | 30% |

| Heat Consumption Reduction | 40% |

| Discharged Flue Gas Temperature | < 250℃ |

| Applications | Nickel extraction, activated limestone calcination, oxidized pellets, magnesium oxide, aluminum oxide, titanium dioxide |