Description

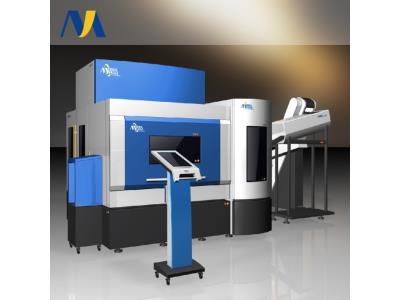

The MG-E Economical Blow Moulding Machine is an innovative and cost-effective solution designed specifically for producing PET and PP stretch blow bottles. With extensive research and development, Mega has launched this state-of-the-art two-stage automatic machine, which optimizes power consumption through its advanced layout and patented preform heating system. This ensures that users can maximize profits in the highly competitive bottle molding market. The machine is engineered for efficiency and flexibility, making it an ideal choice for manufacturers seeking reliable production capabilities.

Specifications

| Feature | Description |

|---|---|

| Machine Type | Two-stage automatic stretch blow moulding machine |

| Suitable Materials | PET and PP |

| Power Consumption | Optimized for economic running |

| Blow Pressure | Up to 40 Bar |

| Mold Size | Fits molds up to 2.5L |

| Heating System | Modular oven with 9 layers of heating lamps |

| Controller | Microprocessor with 30 sets of memory storage |

| Preform Feed | Automated conveyor sorting neck upwards |

Additional Information

- PID System: Infrared thermometer adjusts oven temperature automatically, compensating for temperature variations.

- Air Recovery System: Recovers up to 30% of exhausted high-pressure air to reduce production costs.

- Air Cooling System: Designed for hot fill PET bottles to minimize residual stress and enhance crystallization rates.

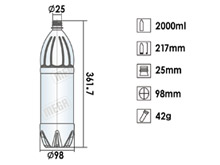

CSD-PET-bottle-2L

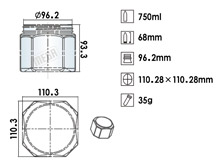

Jar-750ml

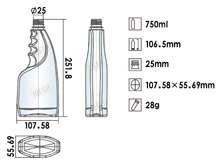

Detergen-750ml

Pharmacal-bottle 135ml

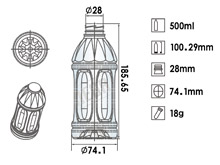

Hot-fill-500ml

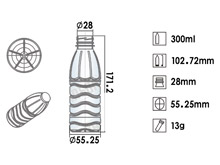

Water-bottle-300ml