Description

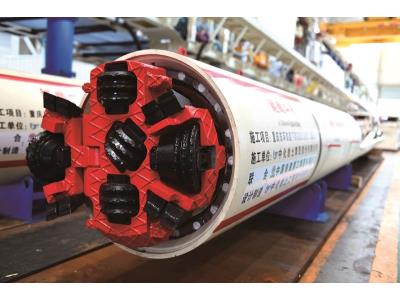

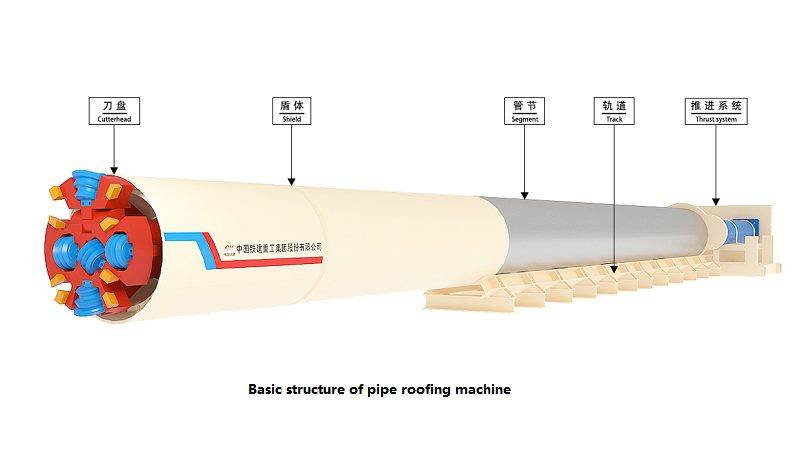

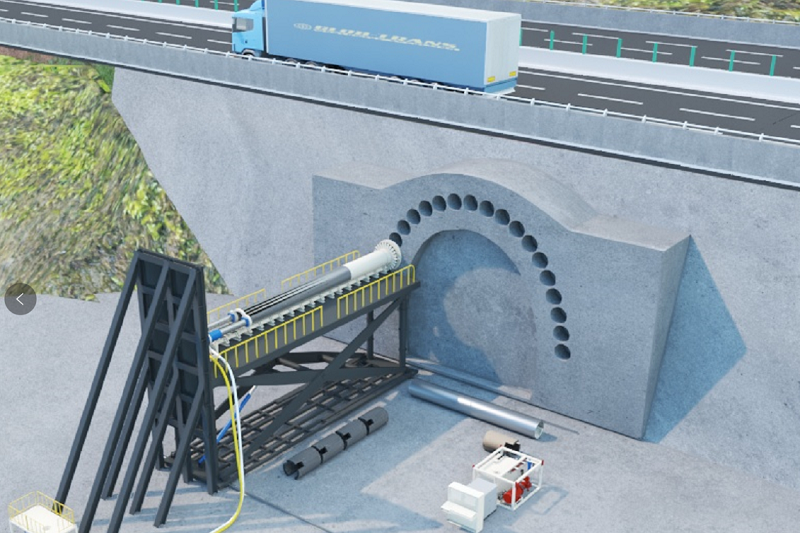

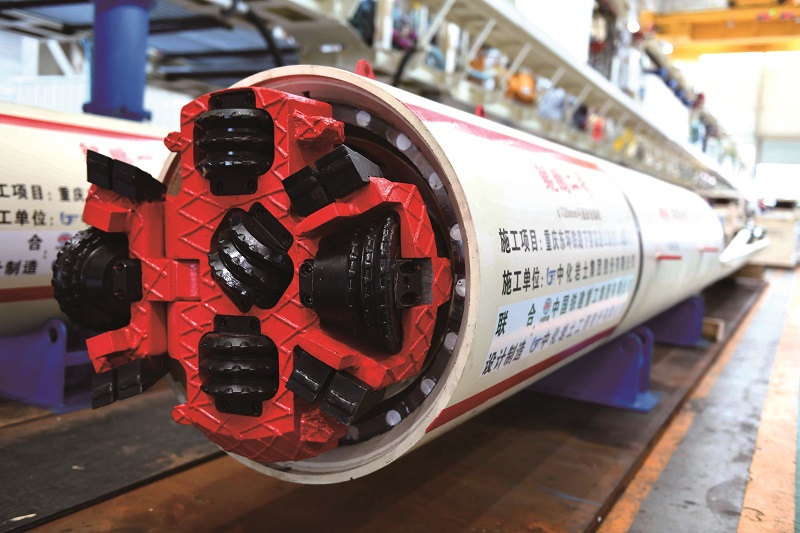

The Pipe Roofing Machine is an innovative trenchless construction technology designed to support soil on the periphery of tunnel faces by constructing pipe roofs. This state-of-the-art machine ensures safe excavation, especially in challenging environments like those intersecting existing highways or railways. Utilizing a pipe jacking technique, steel tubes are inserted into the ground, forming a protective structure that allows for secure tunneling operations.

Working Principles: The machine operates by jacking steel tubes into the soil from a launching shaft to a reception shaft. These tubes interconnect through lock mouths, creating a complete tube system. Waterproofing additives are then injected into the gaps to prevent water ingress, allowing for safe tunnel excavation under the protection of the pipe roofs.

Specifications

| Attribute | Details |

|---|---|

| Project | Chongqing Railway East Loop Project |

| Machine Type | Pipe roofing machine with slurry support |

| Geology | Artificial fill, clay, mudstone, sandstone |

| Machine Data | 3 * pipe roofing machines |

| Excavation Diameter | 720 mm |

| Length of Shield + Back-up | 12 m |

| Weight | 63 t |

| Installed Power | 93 kW |

| Nominal Torque | 25 kNm |

| Maximum Thrust | 4000 kN |

| Performance | Average daily advance rate: 15 m Maximum daily advance rate: 18 m |

Additional Information

Features of CRCHI’s Pipe Roofing Machine:

- Composite cutterhead capable of handling various complex geologies.

- Pull-out functionality allows for multiple uses and access to address obstacles.

- Slurry balance method for precise control of tunnel face pressure and reduced ground settlement.

- Automatic measurement system for accurate posture feedback.

- Articulation device for precise deviation correction and direction adjustment.