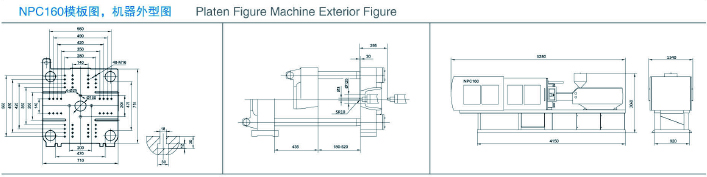

OEM ODM PLASTIC INJECTION MOLDING MACHINE NPC 160

Description

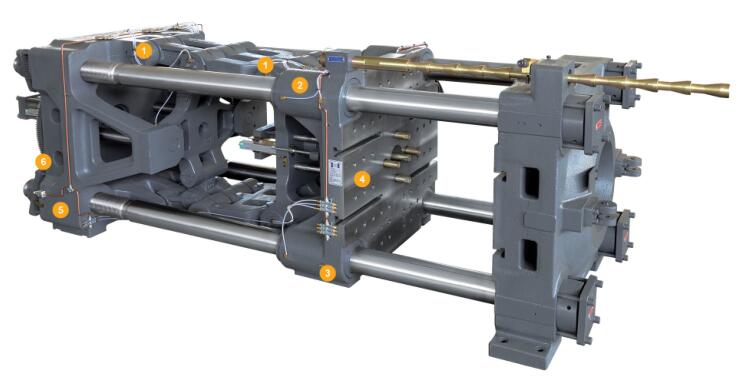

The Plastic Injection Molding Machine NPC 160 is engineered for precision and stability in the manufacturing process. This advanced machine features a robust clamping unit designed with strong rigidity to ensure stable operation. Its diagonal type dual toggle mechanism offers enhanced support, while a one-piece casting of the connecting rod guarantees smooth movement and reduced wear during operation. The machine is equipped with a centralized lubrication system and automatic mold adjustment functionality, making it user-friendly and efficient for various production needs.

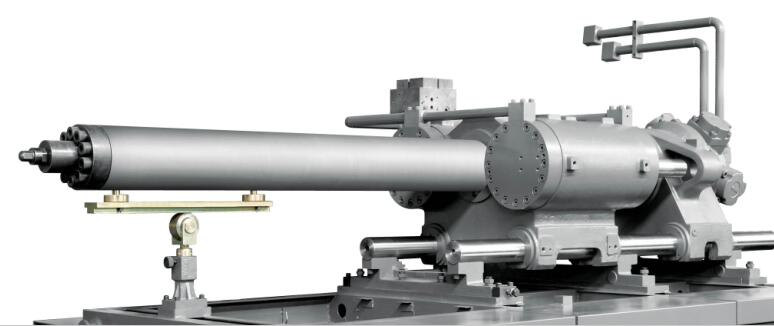

In addition, the injection unit boasts a dual-cylinder balanced injection system, allowing for precise control over injection pressure, speed, and position. The inclusion of high-torque oil motor drives and advanced PID temperature control enhances the overall performance, ensuring accurate and consistent results. The hydraulic unit uses imported components for improved response speed and efficiency, while the high-end controller offers complete production network management, connecting cloud data and client terminals for seamless operation.

Specifications

| Feature | Description |

|---|---|

| Clamping Mechanism | Diagonal type dual toggle with one-piece casting |

| Injection System | Dual-cylinder balanced injection with multi-stage control |

| Hydraulic Components | Imported, enhances response speed and efficiency |

| Controller | High-end production network management solution |

Additional Information

The NPC 160 is designed for optimal maintenance with features such as a centralized manual lubricating device and a screw speed tester. The machine’s construction and technology are aimed at reducing wear and ensuring longevity, making it a reliable choice for high-volume production environments.