Description

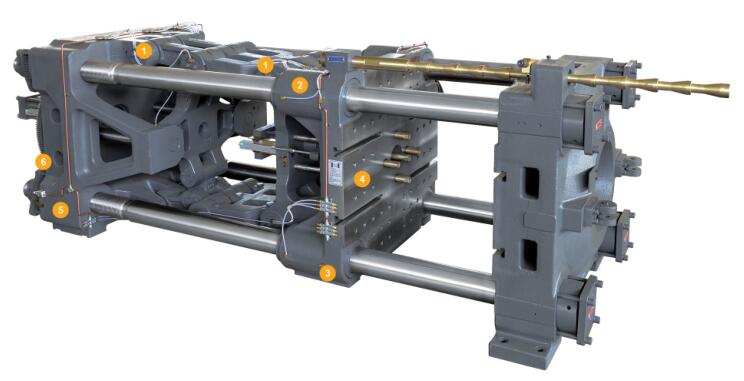

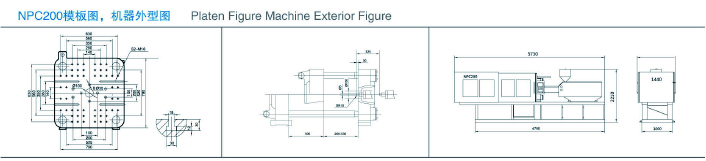

The Plastic Injection Molding Machine NPC 200 is designed for precision and reliability in the production of plastic components. This advanced machine features a robust clamping unit that ensures strong rigidity and stable operation, utilizing a diagonal type dual toggle mechanic for effective mold clamping. With an automatic centralized lubrication system and a standard interface for neutron devices, the NPC 200 is engineered for efficiency and ease of maintenance.

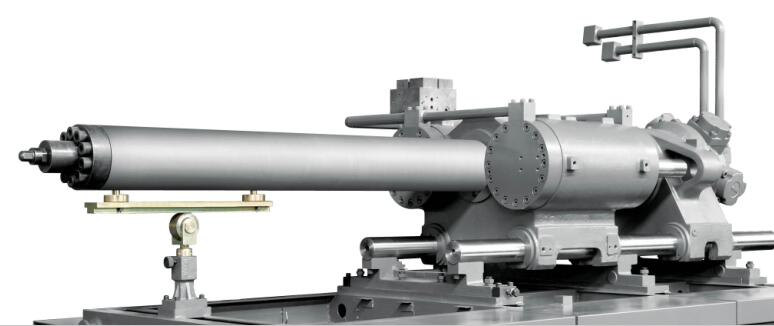

Its injection unit boasts a dual-cylinder balanced injection system for accurate injection and stable operation. The machine supports multi-stage injection pressure, speed, and position control, ensuring high-quality production. The hydraulic unit incorporates imported components, enhancing the system’s response speed and reliability.

Equipped with a high-end controller, the NPC 200 enables complete production network management, allowing for data cloud connectivity and real-time monitoring of production states. With features designed for user-friendliness, such as a one-key mold opening and closing function, this machine minimizes wear and maximizes efficiency.

Specifications

| Feature | Details |

|---|---|

| Clamping Mechanism | Diagonal type dual toggle, one-piece casting connecting rod |

| Lubrication | Automatic centralized lubrication system |

| Injection System | Dual-cylinder balanced injection with multi-stage control |

| Hydraulic Components | Imported components for improved response speed |

| Controller | High-end controller with production network management |

Additional Information

This machine is designed to reduce vibration during operation, enhancing machine life and yield. Users can benefit from fast and smooth mold operation, high-pressure clamping without impact, and easy maintenance through a centralized manual lubricating device.