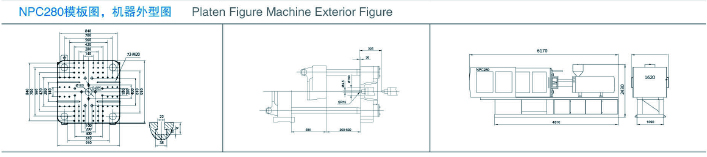

OEM ODM PLASTIC INJECTION MOLDING MACHINE NPC 280

Description

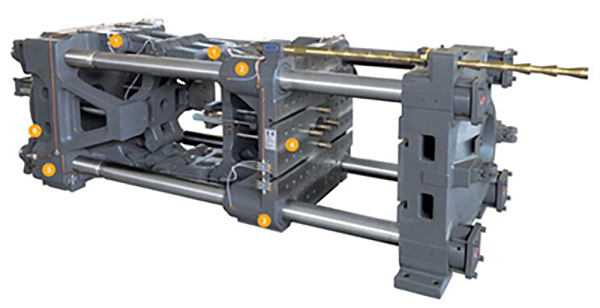

The Plastic Injection Molding Machine NPC 280 is engineered for precision and reliability in plastic manufacturing. This advanced machine features a robust clamping unit designed for strong rigidity and stable operation, ensuring high-quality mold clamping through its diagonal type dual toggle mechanic. With a one-piece casting design, it minimizes wear and enhances the longevity of the machine.

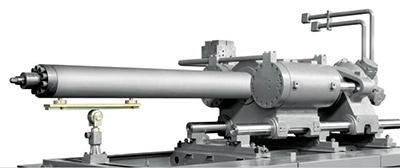

The injection unit employs a dual-cylinder balanced injection system that guarantees accurate injection and stable operation. It incorporates advanced controls for multi-stage injection pressure, speed, and position, ensuring optimal performance across various applications. The hydraulic unit uses high-end imported components to improve response speed and efficiency.

Equipped with a high-end controller, the NPC 280 offers a complete production network management solution, allowing for real-time analysis and supervision of the injection molding process. This machine is designed to enhance productivity while minimizing wear and tear, making it an ideal choice for manufacturers seeking reliability and efficiency.

Specifications

| Feature | Description |

|---|---|

| Clamping Unit | Diagonal type dual toggle mechanic, one-piece casting, automatic lubrication, and mold adjustment features. |

| Injection Unit | Dual-cylinder balanced injection system with multiple pressure and speed controls, ceramic hopper heating device. |

| Hydraulic Unit | Imported hydraulic components for improved response speed and energy efficiency. |

| Controller | Complete production network management with cloud connectivity and real-time analysis capabilities. |

Additional Information

The NPC 280 is designed for ease of use with features like one-key mold opening and closing. Fast and smooth operation minimizes machine wear, while high-pressure clamping extends the machine’s service life. It is ideal for manufacturers looking to optimize their production efficiency.