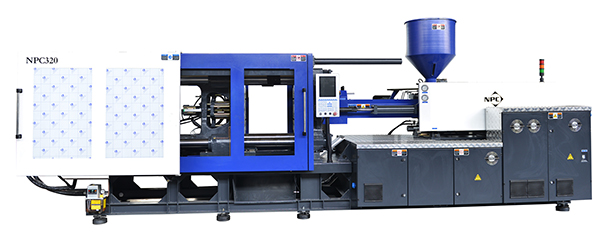

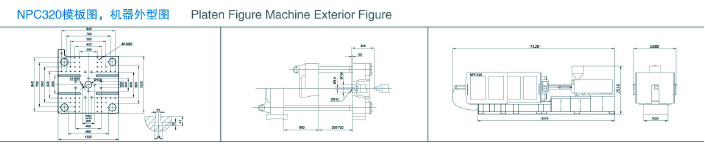

OEM ODM PLASTIC INJECTION MOLDING MACHINE NPC 320

Description

The Plastic Injection Molding Machine NPC 320 is a state-of-the-art solution designed for precision and efficiency in manufacturing. Featuring a robust clamping unit, this machine ensures strong rigidity and stable operation, enhancing productivity. Its innovative design includes a diagonal type dual toggle mechanism, a one-piece casting of the connecting rod for improved rigidity, and a triple interlocking protection system for safety. The automatic lubrication system and mold adjustment functionality further streamline operations, making the NPC 320 an ideal choice for high-volume production.

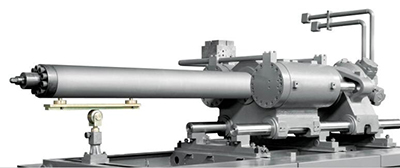

The injection unit is equally impressive, boasting a dual-cylinder balanced injection system that guarantees accurate injection with stable operation. It features multi-stage injection pressure and speed control, ensuring adaptability for various production requirements. The hydraulic unit utilizes imported components to enhance response speed and efficiency, while the high-end controller offers complete production network management, enabling real-time monitoring and process optimization.

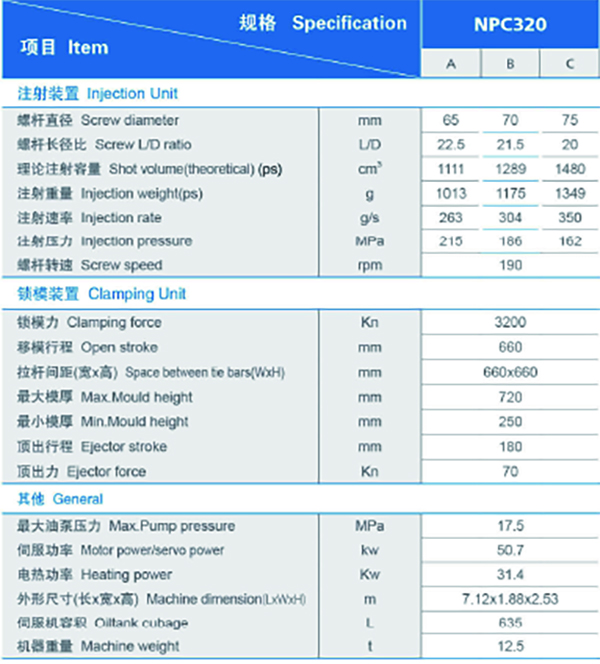

Specifications

| Feature | Description |

|---|---|

| Clamping Mechanism | Diagonal type dual toggle, one-piece casting connecting rod, triple mechanical/hydraulic/electrical interlocking protection |

| Injection System | Dual-cylinder balanced injection, multi-stage pressure/speed control |

| Hydraulic System | Imported components, optimized oil circuit, energy-saving servo control |

| Controller | Complete production network management solution, data cloud connectivity |

Additional Information

The NPC 320 is designed to minimize machine wear and extend operational life. It features a one-key setting for mold opening and closing, ensuring ease of use. The machine operates with high pressure clamping without impact, contributing to its longevity.