OEM ODM PLASTIC INJECTION MOLDING MACHINE NPC 500

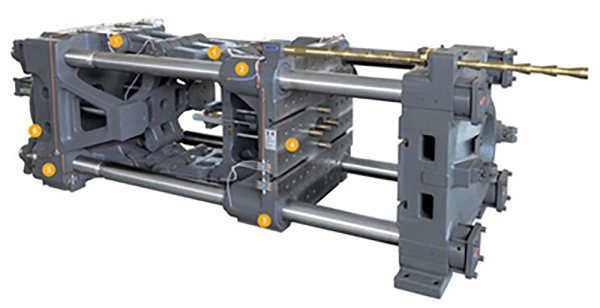

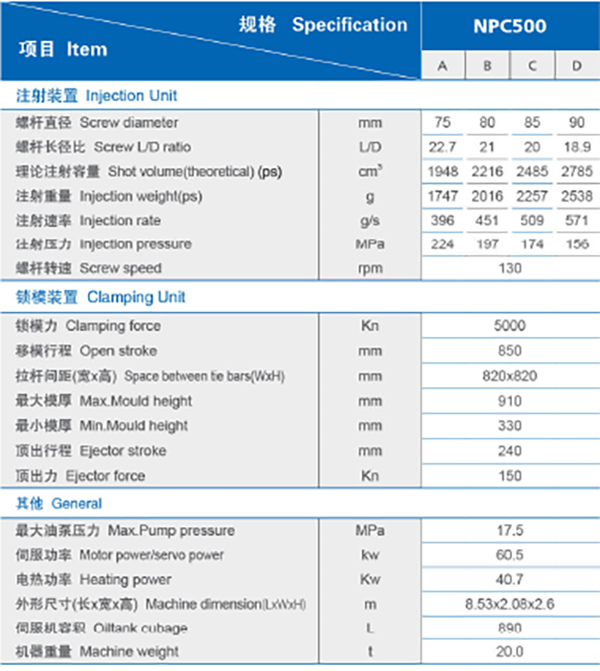

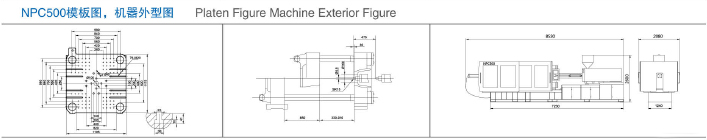

The Plastic Injection Molding Machine NPC 500 is engineered for precision and reliability in manufacturing. This advanced machine features a robust clamping unit that ensures strong rigidity and stable operation. Its diagonal type dual toggle mechanic mold clamping mechanism, along with a one-piece casting of the connecting rod, enhances durability and reduces wear during operation. The NPC 500 is equipped with an automatic centralized lubrication system and an automatic mold adjustment function, streamlining maintenance and enhancing efficiency.

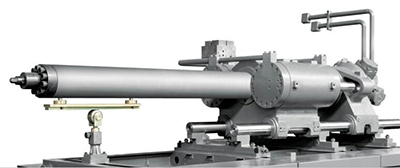

The injection unit guarantees accurate injection and stable operation, utilizing a dual-cylinder balanced injection system and multi-stage control for pressure, speed, and position. The high-torque oil motor drives the screw pre-plasticizing device, ensuring optimal performance. The hydraulic unit employs imported components to improve response speed and overall system efficiency.

Additionally, the high-end controller provides a complete production network management solution, enabling real-time monitoring and adjustments. This combination of features makes the NPC 500 an ideal choice for businesses seeking high-quality, efficient injection molding solutions.

| Feature | Description |

|---|---|

| Clamping Unit | Dual toggle mechanic, one-piece casting, automatic lubrication |

| Injection Unit | Dual-cylinder balanced injection, multi-stage control |

| Hydraulic Unit | Imported components, optimized oil circuit |

| Controller | Network management solution, real-time monitoring |

For optimal performance, ensure regular maintenance of the lubrication system and monitor the hydraulic components for any signs of wear. The NPC 500 is designed for high efficiency and longevity, making it a valuable investment for your production needs.