Description

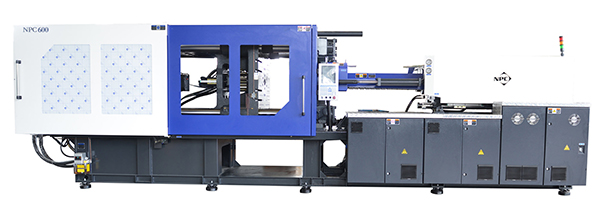

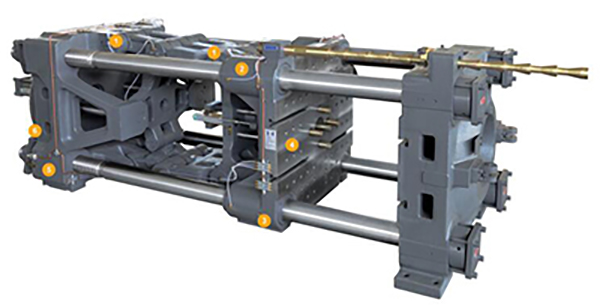

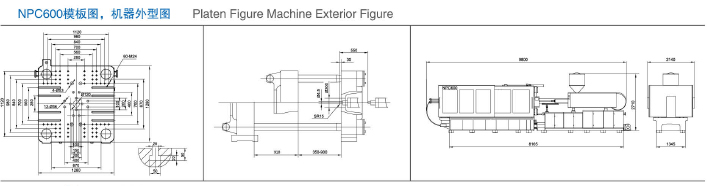

The Plastic Injection Molding Machine NPC 600 is engineered for precision and reliability in manufacturing. This advanced machine features a robust clamping unit that ensures strong rigidity and stable operation. It is equipped with a diagonal type dual toggle mechanical clamping mechanism and a one-piece casting connecting rod, enhancing movement and reducing wear on the die. The automatic lubrication system and centralized mold adjustment function streamline operations, ensuring efficient production.

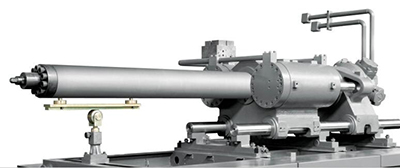

Additionally, the injection unit provides accurate injection and stable operation through its dual-cylinder balanced injection system. The system incorporates multi-stage pressure/speed control for optimal performance. The hydraulic unit utilizes high-quality imported components to improve response speed and energy efficiency, making the NPC 600 a top choice for modern manufacturing needs.

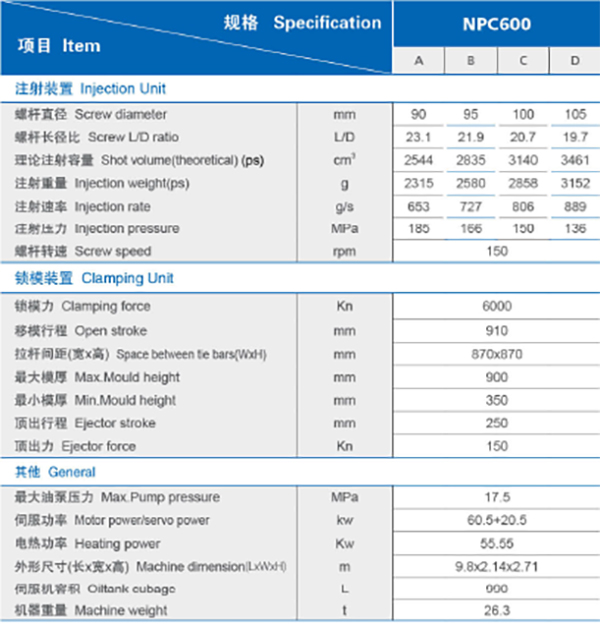

Specifications

| Feature | Description |

|---|---|

| Clamping Unit | Diagonal type dual toggle mechanic mould clamping mechanism, one-piece casting connecting rod, automatic lubrication system |

| Injection Unit | Dual-cylinder balanced injection system, multi-stage injection pressure/speed control |

| Hydraulic Unit | Imported hydraulic components, energy-saving servo control system, optimized oil circuit control |

| Controller | High-end controller for production management, data cloud connectivity |

Additional Information

The NPC 600 is designed to minimize vibrations during mold unlocking, ensuring smooth operation and extending machine life. It offers one-key mold opening and closing for user convenience, alongside high-pressure clamping that operates without impact.