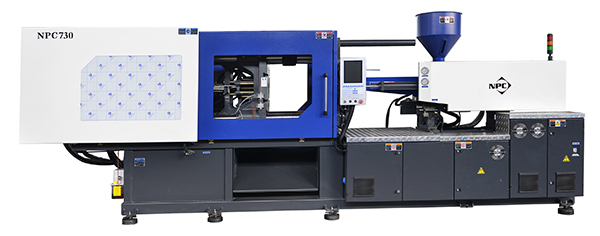

OEM ODM PLASTIC INJECTION MOLDING MACHINE NPC 730

Description

The Plastic Injection Molding Machine NPC 730 is engineered for high precision and robust performance in the production of intricate molded parts. This advanced machine features a clamping unit with strong rigidity and stable operation, ensuring optimal mold handling and longevity. The dual toggle mechanic clamping mechanism and one-piece casting of the connecting rod enhance stability, while the automatic centralized lubrication system keeps the components running smoothly.

Designed for accuracy, the injection unit utilizes a dual-cylinder balanced injection system, allowing for multi-stage pressure and speed control. The hydraulic unit incorporates imported components that significantly improve response speed and efficiency, while the high-end controller facilitates comprehensive production management, connecting data cloud and client terminals for real-time monitoring and analysis. This machine is ideal for manufacturers seeking efficiency, reliability, and precision in their production line.

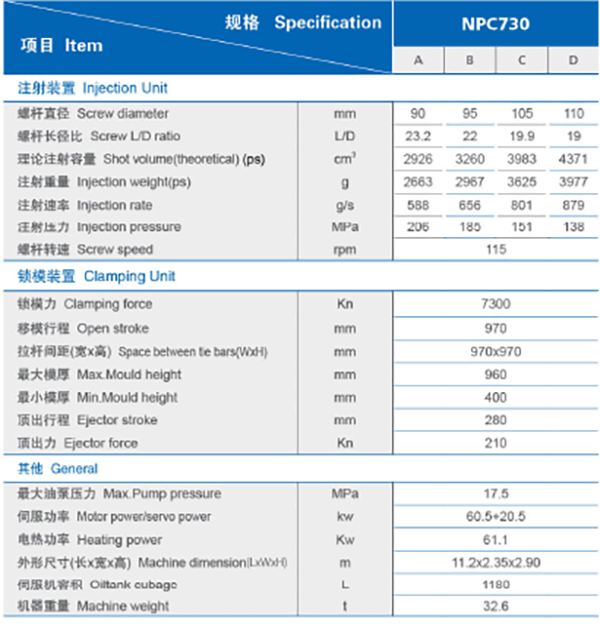

Specifications

| Feature | Description |

|---|---|

| Clamping Mechanism | Diagonal type dual toggle with strong rigidity and stability |

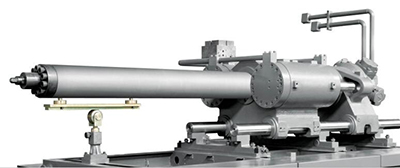

| Injection System | Dual-cylinder balanced injection with multi-stage control |

| Hydraulic System | Imported components for improved efficiency and response |

| Controller | High-end controller with network management solutions |

| Lubrication System | Automatic centralized lubrication for ease of maintenance |

Additional Information

This machine incorporates a series of advanced features including:

- High-torque oil motor drive for the screw preplasticizing device

- Precise hydraulic power device for stable operation

- One-key mold opening and closing for user-friendly operation

- Energy-saving servo control system to reduce operational costs