Description

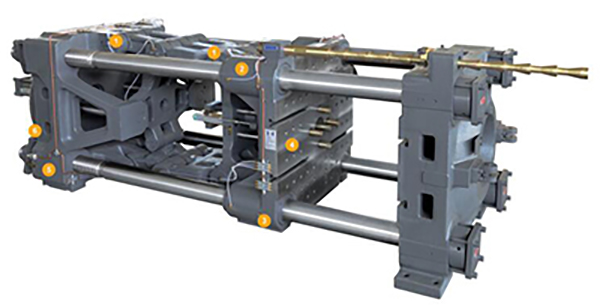

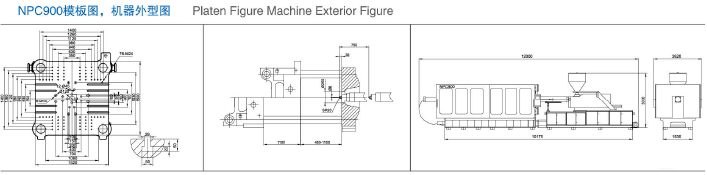

The Plastic Injection Molding Machine NPC 900 is a state-of-the-art solution designed for high precision and efficiency in industrial applications. Engineered with strong rigidity and stability, the machine features a diagonal type dual toggle mechanic mold clamping mechanism, ensuring reliable operation. Its optimized one-piece front connecting rod enhances rigidity while minimizing wear during operation. The NPC 900 is equipped with an automatic centralized lubrication system and an automatic mold adjustment function, streamlining maintenance and enhancing productivity.

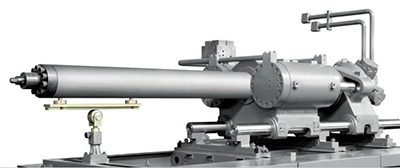

With a dual-cylinder balanced injection system, this machine guarantees accurate injection and stable operation. The multi-stage injection pressure and speed control allows for precise molding of various products. The hydraulic unit utilizes imported components to improve the system’s responsiveness and efficiency, while the high-end controller offers comprehensive production management capabilities, connecting data cloud and client terminals for seamless operations.

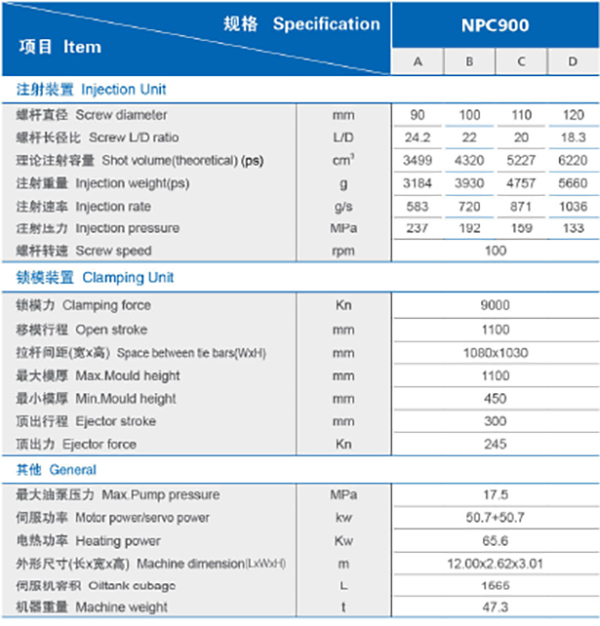

Specifications

| Feature | Description |

|---|---|

| Clamping Unit | Diagonal type dual toggle mechanic, one-piece casting, triple interlocking protection, and automatic lubrication. |

| Injection Unit | Dual-cylinder balanced system, multi-stage pressure/speed control, and high-torque motor drive. |

| Hydraulic Unit | Imported components, precise control elements, and optimized multi-pump system. |

| Controller | Complete production network management with cloud data integration. |

Additional Information

The NPC 900 features a centralized manual lubricating device for easy maintenance and is designed to reduce vibration during operations, extending the machine’s lifespan. Its user-friendly interface allows for quick mold settings, ensuring efficiency in production processes.