Description

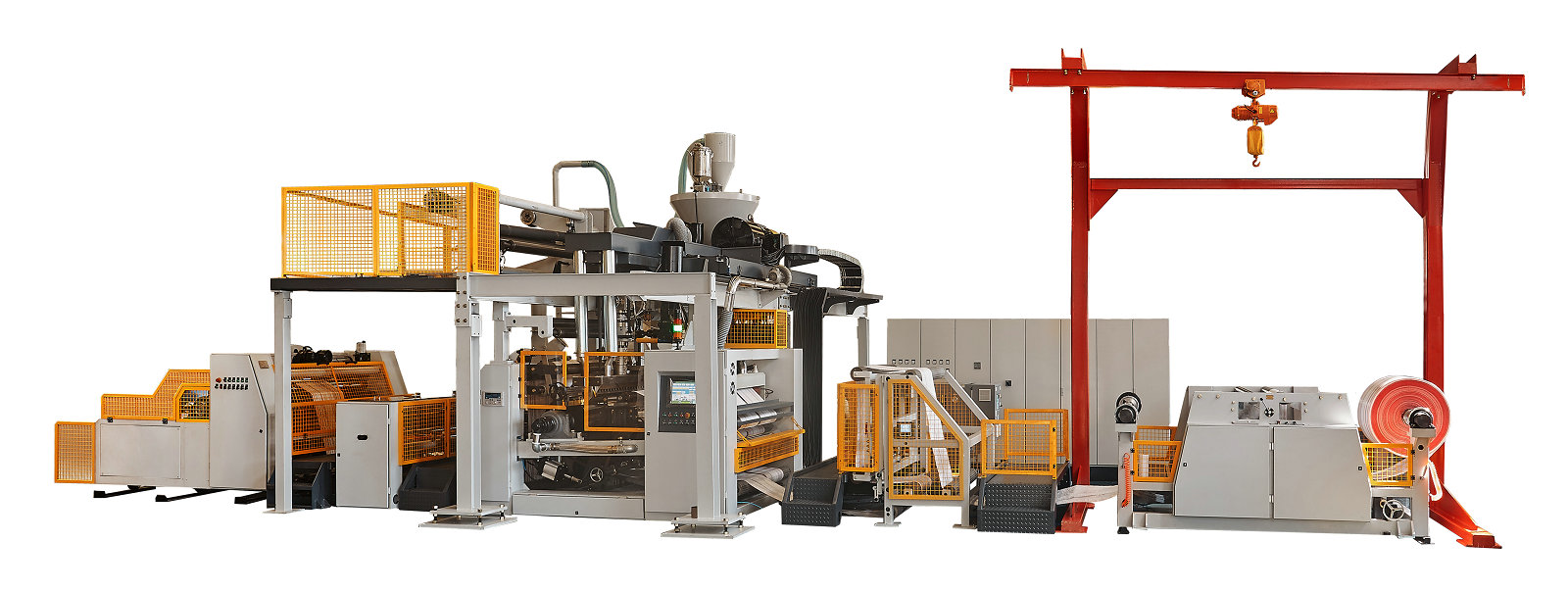

The PLASTIC SINGLE DIE EXTRUSION LAMINATION LINE, model SJFM-Z, is designed to enhance the waterproof and anti-seepage capabilities of various industrial fabrics. This advanced single die plastic coating line efficiently laminates the surface of PP/HDPE woven fabric and a wide range of other materials. It supports double-sided coating for AD Star bags and small woven bags, as well as BOPP laminating, flat fabric single-side coating, aluminum foil laminating, kraft paper, and non-woven fabric laminating.

With a remarkable running speed of 220m/min, this machine features a Human-Machine Interface (HMI) for central control, ensuring a high level of automation and ease of operation. It allows for non-stop changing of fabric rolls and includes an auto cut feature for winding length setting. The system also incorporates a flexible and reliable photoelectrical edge trimming mechanism for precise edge size control and a waste edge online recycling system that reduces material waste, thereby increasing production efficiency.

Specifications

| Feature | Details |

|---|---|

| Model | SJFM-Z |

| Running Speed | 220 m/min |

| Coating Types | AD Star bags, small woven bags, BOPP, flat fabric, aluminum foil, kraft paper, non-woven fabric |

| Control System | HMI Central Control |

| Automation Level | High |

| Edge Trimming System | Photoelectrical |

| Waste Recycling System | Online Recycling |

Additional Information

The PLASTIC SINGLE DIE EXTRUSION LAMINATION LINE is engineered for efficiency and precision, making it an ideal choice for manufacturers seeking to enhance their production capabilities while minimizing material waste.