Description

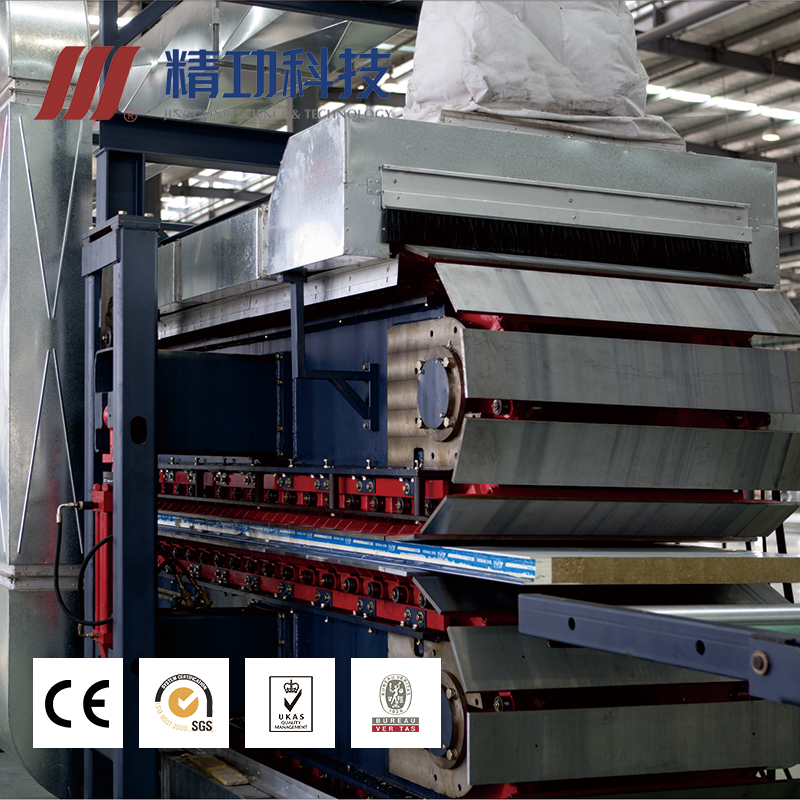

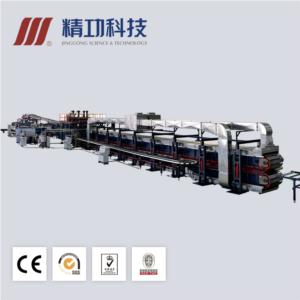

The PU/PIR/Rockwool Sandwich Panel Machine is an advanced automated production line designed for manufacturing high-quality sandwich panels. This versatile machine combines multiple functions, including thermal insulation, sound isolation, and flame retardance, making it ideal for various construction applications. Its innovative design features a heated air recycle oven that ensures precise temperature control during PU foaming and solidification. By utilizing a high-pressure foaming system, the machine guarantees accurate measurements, high stability, and minimal dust generation, promoting a healthier working environment.

Moreover, the machine employs eco-friendly foaming agents such as 141B or Pentane, replacing harmful carbon chloral-fluoride, thus ensuring environmentally responsible production practices. The specially designed double belt conveyor contributes to a flat surface on the sandwich panels, ensuring uniform thickness and an anti-pattern finish. Controlled by a PLC computer system, the operation is user-friendly, allowing for easy customization and management of the production process.

Specifications

| Feature | Description |

|---|---|

| Type | Automatic Production Line |

| Functions | Thermal Insulation, Sound Isolation, Flame Retardance |

| Temperature Control | Heated Air Recycle Oven |

| Foaming System | High Pressure with Precise Measurement |

| Foaming Agent | 141B or Pentane |

| Conveyor Type | Special Double Belt Conveyor |

| Control System | PLC Computer Controlled |

Additional Information

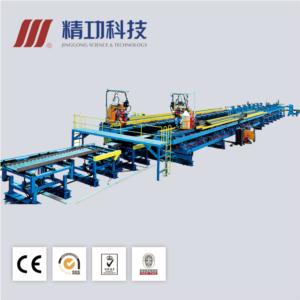

The JF100 type PU sandwich panel line includes a comprehensive setup consisting of a decoiler, film coating, pre-cutting, cutting equipment, roll forming system, preheating, foaming solidification, band saw cutting, cooling, stacking, and packing. This all-in-one solution integrates advanced technologies from multiple fields, including mechanics, chemistry, electrical control, hydraulic pressure, pneumatic operations, and temperature control.