Description

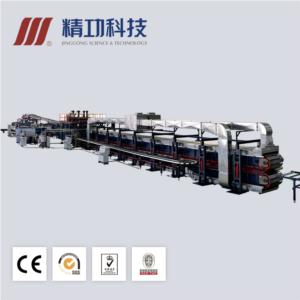

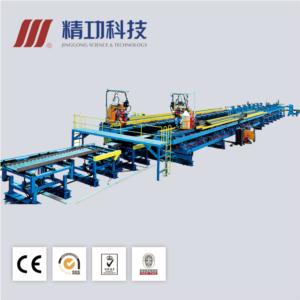

The JF100 type PU sandwich panel line is a state-of-the-art automatic production system designed for the efficient manufacturing of polyurethane composite plates. This comprehensive line comprises essential components including a decoiler, film coating, pre-cutting, cutting equipment, roll forming system, preheating, foaming, solidification, band saw cutting, cooling, stacking, and packing. Integrating advanced technologies across various fields such as mechanics, chemistry, electrical control, hydraulic pressure, pneumatic, and temperature control, this production line is engineered for optimal performance.

Key features include:

- Versatile Functionality: Provides thermal isolation, sound isolation, and flame retardance.

- Temperature Control: A heated air recycle oven ensures precise control of PU foaming and solidification temperatures.

- Health-Conscious Design: High-pressure foaming system with precise measurements minimizes dust in the workplace.

- Environmentally Friendly: Utilizes 141B or C5 as a foaming agent, eliminating carbon chlorofluoride for a greener production process.

- Special Conveyor System: Features a double belt conveyor for a flat sandwich panel surface and uniform thickness.

- User-Friendly Operation: PLC computer-controlled system for personalized design and simplified operation.

Specifications

| Item | Parameter | |

|---|---|---|

| Material | Type | Color steel sheet; galvanized sheet, Aluminum sheet |

| Thickness | 0.4-0.8 | |

| Width | ≤1250(Max) | |

| Suitable size of panel | Length | 2000-16000 |

| Width | 600-1200 | |

| Thickness | 30-200 (Not including height of corrugation) | |

| Production speed | 3-8 (Adjustable) | |

| Valid length of double belt conveyor (mm) | 16000-36000 | |

| Work pressure on pouring foam | 150-200 | |

| Total power | About 300 | |

| Total size (Length × Width × Height) (mm) | 130000 × 15000 × 6000 |

Additional Information

The JF100 type PU sandwich panel line is designed for high efficiency and safety, ensuring a reliable production process while prioritizing worker health and environmental sustainability. Ideal for various industrial applications, this production line delivers high-quality sandwich panels that meet diverse customer needs.