Description

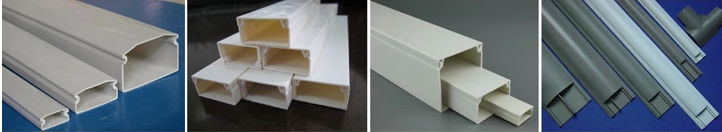

The PVC cable trunkings and cable pipes extrusion line is an advanced manufacturing solution designed for high efficiency and stability in the production of U channel profiles and PVC conduit pipes. This versatile system serves as an essential tool for creating PVC electrical cable trunking, cable ducts, and conduit pipes. Comprising a conical twin-screw extruder, vacuum calibration table, haul-off unit, cutter, and stacker, it ensures a seamless production process. By changing the extruding molds, the machine can also produce various PVC profiles such as door frames, window frames, and floor tile profiles.

The extrusion process follows a systematic approach: PVC powder and additives are mixed and fed into the extruder, where they are shaped into desired profiles before being calibrated, cut, and stacked as finished products.

Specifications

| Machines List | Quantity |

|---|---|

| Raw materials Mixing system | |

| 1. Spiral Loader | 1 set |

| 2. High speed Heating/Cooling Mixer unit | 1 set |

| PVC profiles Extrusion machines | |

| 1. Spring Loader | 1 set |

| 2. KBL55/113 or KBL65/132 Conical twin-screw extruder | 1 set |

| 3. Vacuum calibration Table | 1 set |

| 4. Haul off and Cutter unit | 1 set |

| 5. Stacker | 1 set |

| PVC profiles Recycling system | |

| 1. PVC profiles Crusher | 1 set |

| 2. PVC Pulverizer | 1 set |

Additional Information

Remarks: Above information is for your reference, please contact us for more detailed information and machine projects.