Description

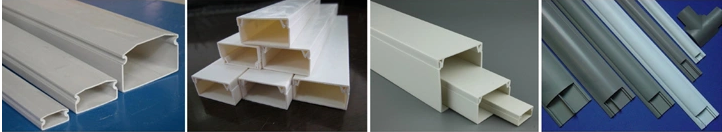

The PVC cable trunkings and cable pipes extrusion line is a high-efficiency, stable, and easy-to-operate machine designed for the production of U channel profiles and PVC conduit pipes. This versatile equipment is ideal for manufacturing PVC electrical cable trunking, cable ducts, conduit pipes, and cable pipes. The production line comprises a conical twin-screw extruder, vacuum calibration table, haul-off, cutter, and stacker, ensuring a streamlined process from raw materials to finished products. With the ability to change extruding molds, this machine can also produce PVC door frames, window profiles, and floor tile profiles.

The extrusion process is straightforward: PVC powder and additives are mixed, fed into the extruder, molded, calibrated, and finally cut and stacked into the finished products.

Specifications

| Machines List | Quantity |

|---|---|

| Raw materials Mixing system | |

| 1. Spiral Loader | 1 set |

| 2. High speed Heating/Cooling Mixer unit | 1 set |

| PVC profiles Extrusion machines | |

| 1. Spring Loader | 1 set |

| 2. KBL55/113 or KBL65/132 Conical twin-screw extruder | 1 set |

| 3. Vacuum calibration Table | 1 set |

| 4. Haul off and Cutter unit | 1 set |

| 5. Stacker | 1 set |

| PVC profiles Recycling system | |

| 1. PVC profiles Crusher | 1 set |

| 2. PVC Pulverizer | 1 set |

Additional Information

Remarks: Above information is for your reference; please contact us for more detailed information and machine project specifics.