#### **Description**

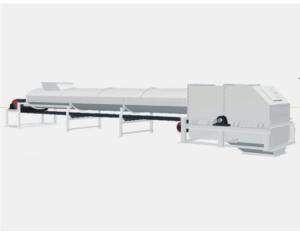

The QDG Series of Air Cushion Belt Conveyor is a cutting-edge solution designed for long-distance material transportation. This innovative conveyor system boasts numerous advantages, including minimal trouble points, excellent sealing capabilities, an extended service life, high conveying yield, and stable, reliable operation while consuming low energy. The head wheel features a rubber coating to enhance friction, preventing belt skidding and improving transmission efficiency. Additionally, a specialized scraper cleaning device ensures that all materials are effectively discharged into the head hopper.

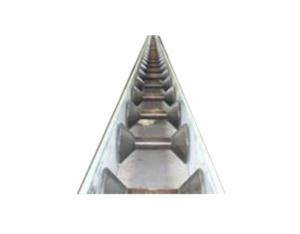

The design incorporates an independent air supply section throughout the conveyor’s length, minimizing airflow impact and preventing pressure loss during long-distance conveyance. Air escape valves are strategically positioned to allow surplus gas to escape, ensuring the conveyor belt remains stable. The QDG Series also offers various tensioning modes, such as screw tension, fixed guide-rail gravity tension, and side trolley tension, tailored to specific equipment lengths and service conditions. Safety features include inspection doors, observation windows, dust-collection exhaust inlets, speed detection, disalignment, anti-blockage mechanisms, and axle temperature detection, making it a reliable choice for diverse industries.

#### **Specifications**

| Feature | Details |

|---|---|

| Type | Air Cushion Belt Conveyor |

| Conveying Capacity | High |

| Energy Consumption | Low |

| Application Industries | Building materials, coal, chemical, pharmaceutical, food, feed |

| Material Types | Granular, flaky, powdery |

| Maintenance Cost | 50% less than roller belt conveyors |

#### **Additional Information**

This conveyor system is designed for large capacity and long-distance transportation, making it ideal for various industrial applications. Its simple structure and reduced number of wearing parts contribute to its cost-effectiveness and ease of maintenance. The QDG Series can function independently or in conjunction with other conveying equipment to form horizontal or inclined conveyor systems.